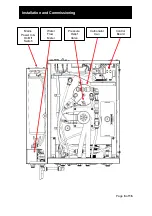

Installation and Commissioning

Page

5

of

16

• Before turning on the water supply locate the flush valve at the front

of the filter housing and turn the lever to the ‘Flush Position’. Connect

the clear PVC tubing supplied to the flush outlet and place the other

end of the tubing into an empty bucket or to a drain.

• Turn on the water supply. Water will now begin to flow through the

water filters and the flowmeter will display a flow rate. When the

filters are full, water will flow out of the clear tubing. Initially the water

will contain some sediment from the carbon filtration, this is normal,

allow to flow until clear.

• Once clear, turn the flush valve lever back through 180° into the ‘Unit

Supply Position’. Water will now be directed into the water circuit of

the unit.

• Open the still tap until water flows (this may take a few seconds as

the cooling coil inside the unit fills with water) then close. At this

stage re-fit the lid and filter housing cover.

• Turn on the electrical supply. After a short delay the fridge system

will activate (check for air exhausting to the rear of the machine) and

the carbonator can fill pump will activate; once the can is filled the

pump will automatically switch off.

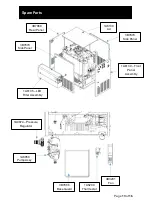

• To ensure all air is purged from the carbonator can, turn off the

electrical supply and dispense sparkling water until the can is

empty, then allow gas to flow from the dispense tap for 5 secs.

• Restore the electrical supply. The fridge system and can fill pump will

activate as before and the can pump will switch off when the can is

full. When the compressor and fans switch off the unit is ready.

• Depending on the ambient temperature and the temperature of the

incoming water the time required for the fridge system to switch off

can take 3 to 5 hours. In very high ambient conditions (90°F/32°C or

higher) the time required may be over 5 hours.

• Note: If the bath has been filled to the point of overflow,

approximately 17 fl oz (0.5 liters) of water will be displaced as ice

forms in the bath.