TESTING –

IMPORTANT! Do not test or run disposer dry as this will damage the seal and void the warranty.

1

. Test assembly for leaks:

a. where cone joins table

b. where disposer joins cone

c. all piping connections

d. “Swirl Spray” fittings

2

. After plumbing and electrical connections are made, turn on disposer to be sure all parts are in working order and that the disposer turntable

rotates clockwise when viewed from above. Open valve in vacuum breaker line, and using valves in plumbing assembly (Fig.7), adjust so

that water swirls around just below the rim of the cone sink. Leave valves in these positions. These combinations provide a flow of approxi-

mately 8 gallons of water per minute.

3

. Replace cover, retest for leaks and turn unit off.

4

. Unit is now ready for operation.

560P333P01 REV B

4240 E. La Palma Avenue, Anaheim, CA 92807 • (800) 454-4423 • fax (800) 246-3245 • www.wasteking.com

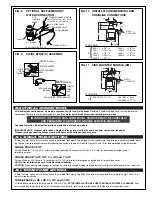

MANUAL SWITCH

MODEL

VOLTS

WK PART NO.

500 –

110-120

2420

1500

220-240

FIG. 12

SINGLE PHASE

FIG. 13

WIRING FOR SINGLE PHASE

UNITS WITH MANUAL SWITCH

FIG. 14

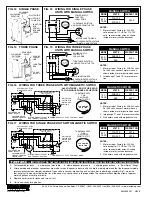

THREE PHASE

FIG. 15

WIRING FOR THREE PHASE

UNITS WITH MANUAL SWITCH

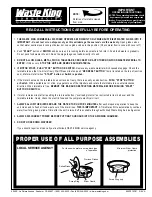

FIG. 16

WIRING FOR THREE PHASE UNITS WITH MAGNETIC SWITCH

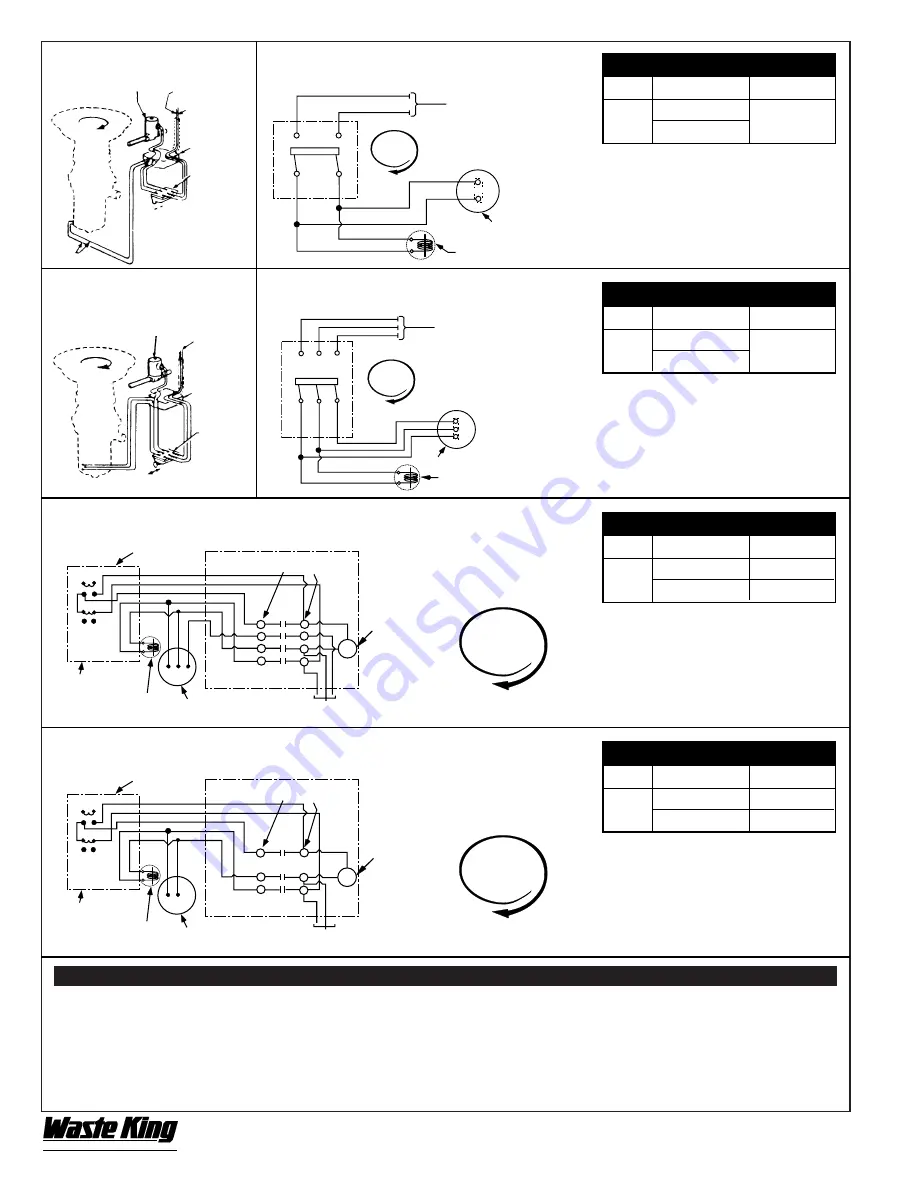

FIG. 17

WIRING FOR SINGLE PHASE UNITS WITH MAGNETIC SWITCH

NOTES:

1. Motor wired at Factory for 220-240

volts except for 1/2 HP. For 110-120

volts, connect motor wires as shown

inside of motor junction box cover.

MANUAL SWITCH

MODEL

VOLTS

WK PART NO.

500 –

208-240

2420

1500

460

NOTES:

1. Motor wired at Factory for 208-240 volts.

For 460 volts, connect motor wires as

shown inside of motor junction box cover.

2. Interchange T1 and T3 to reverse rota-

tion.

MAGNETIC SWITCH

MODEL

VOLTS

WK PART NO.

750 –

208-240

2416

1500

460

2417

NOTES:

1. Motor wired at Factory for 208-240 volts.

For 460 volts, connect motor wires as

shown inside of motor junction box cover.

2. Interchange T1 and T3 to reverse rotation.

3. No heaters used with magnetic switch.

MAGNETIC SWITCH

MODEL

VOLTS

WK PART NO.

500 –

110-120

2414

1500

220-240

2415

NOTES:

1. Motor wired at Factory for 220-240

volts except for 1/2 HP. For 110-120

volts, connect motor wires as shown

inside of motor junction box cover.

2. No heaters used with magnetic switch

L-1

L-2

T-1

T-2

L-1

L-2

T-1 T-2

L-3

T-3

T-3

L-3

T-2

L-2

3

2

T-1

L-1

THESE TERMINALS MAY BE

LABELED T4 OR L4

C L O C K W I S E

R O TAT I O N

C L O C K W I S E

R O TAT I O N

C L O C K W I S E

R O TAT I O N

C L O C K W I S E

R O TAT I O N

C

O

M

M

E

R

C

I

A

L

®

by Anaheim Manufacturing

CLOCKWISE

ROTATION

WHITE WIRE

HOT WIRE

POWER “IN”

SOLENOID

VALVE

ON / OFF

POWER SUPPLY -

FUSE PER

LOCAL CODE

SOLENOID RATED VOLTAGE

TO MATCH LINE VOLTAGE

MOTOR JUNCTION BOX

TURNTABLE ROTATION

AS VIEWED FROM THE TOP

POWER SUPPLY -

FUSE PER

LOCAL CODE

SOLENOID RATED VOLTAGE

TO MATCH LINE VOLTAGE

MOTOR JUNCTION BOX

TURNTABLE ROTATION

AS VIEWED FROM THE TOP

TURNTABLE ROTA-

TION

AS VIEWED

FROM THE TOP

TURNTABLE ROTA-

TION

AS VIEWED

FROM THE TOP

CLOCKWISE

ROTATION

3 PHASE

POWER

LINE

JUNCTION

BOX

3 POLE

SWITCH

SOLENOID

VALVE

ON / OFF

L1

L2

T1

T2

L1

L2

L3

T1

T2

T3

SWITCH START - STOP

(MOUNT NEAR UNIT)

COIL RATED

VOLTAGE TO

MATCH LINE

VOLTAGE

POWER SUPPLY - FUSE PER LOCAL CODE.

MOTOR: CONSULT CHART FOR COR-

RECT MAGNETIC SWITCH

SOLENOID-RATED

VOLTAGE TO MATCH

LINE VOLTAGE

SWITCH BOX ON

FRONT OF UNIT

START

STOP

T-2

L-2

3

2

T-1

L-1

THESE TERMINALS MAY BE

LABELED T4 OR L4

SWITCH START - STOP

(MOUNT NEAR UNIT)

COIL RATED

VOLTAGE TO

MATCH LINE

VOLTAGE

POWER SUPPLY - FUSE PER LOCAL CODE.

MOTOR: CONSULT CHART FOR COR-

RECT MAGNETIC SWITCH

SOLENOID-RATED

VOLTAGE TO MATCH

LINE VOLTAGE

SWITCH BOX ON

FRONT OF UNIT

START

STOP

JUNCTION

BOX

SWITCH

BOX AND

COVER

ALL VOLTAGES – DO NOT USE L3 OR

T3 FOR SINGLE PHASE APPLICATION

®