with tie breakers between the different sections, then the status of each tie breaker is required

for control of the load sharing in isochronous mode.

14.3

Alarm and monitoring signals

Regarding sensors on the engine, the actual configuration of signals and the alarm levels are

found in the project specific documentation supplied for all contracted projects.

14.4

Electrical consumers

14.4.1

Motor starters and operation of electrically driven pumps

Motor starters are not part of the control system supplied with the engine, but available as

loose supplied items.

14.4.1.1

Engine turning device (9N15)

The crankshaft can be slowly rotated with the turning device for maintenance purposes. The

motor starter must be designed for reversible control of the motor. The electric motor ratings

are listed in the table below.

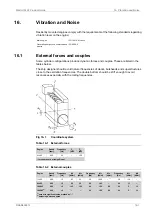

Table 14-1 Electric motor ratings for engine turning device

Current [A]

Power [kW]

Frequency [Hz]

Voltage [V]

Engine type

5

2.2/2.6

50 / 60

3 x 400/440

Wärtsilä 46F

(6L,7L,8L)

12

5.5/6.4

50 / 60

3 x 400/440

Wärtsilä 46F

(9L,V-engines)

14.4.1.2

Pre-lubricating oil pump

The pre-lubricating oil pump must always be running when the engine is stopped. The pump

shall start when the engine stops, and stop when the engine starts. The engine control system

handles start/stop of the pump automatically via a motor starter.

It is recommended to arrange a back-up power supply from an emergency power source.

Diesel generators serving as the main source of electrical power must be able to resume their

operation in a black out situation by means of stored energy. Depending on system design

and classification regulations, it may be permissible to use the emergency generator.

14.4.1.3

Stand-by pump, lubricating oil (if applicable) (2P04)

The engine control system starts the pump automatically via a motor starter, if the lubricating

oil pressure drops below a preset level when the engine is running. There is a dedicated sensor

on the engine for this purpose.

The pump must not be running when the engine is stopped, nor may it be used for

pre-lubricating purposes. Neither should it be operated in parallel with the main pump, when

the main pump is in order.

14.4.1.4

Stand-by pump, HT cooling water (if applicable) (4P03)

The engine control system starts the pump automatically via a motor starter, if the cooling

water pressure drops below a preset level when the engine is running. There is a dedicated

sensor on the engine for this purpose.

DAAB605814

14-5

14. Automation System

Wärtsilä 46F Product Guide

Summary of Contents for 46F Series

Page 1: ...Wärtsilä 46F PRODUCT GUIDE ...

Page 4: ...This page intentionally left blank ...

Page 8: ...This page intentionally left blank ...

Page 18: ...This page intentionally left blank ...

Page 86: ...This page intentionally left blank ...

Page 104: ...This page intentionally left blank ...

Page 154: ...This page intentionally left blank ...

Page 162: ...This page intentionally left blank ...

Page 170: ...This page intentionally left blank ...

Page 176: ...This page intentionally left blank ...

Page 194: ...This page intentionally left blank ...

Page 200: ...This page intentionally left blank ...

Page 202: ...This page intentionally left blank ...

Page 207: ...Fig 21 7 List of symbols DAAF406507 7 DAAB605814 21 5 21 ANNEX Wärtsilä 46F Product Guide ...