INTIG 250 PULSE DC Pulse Argon Welding Machine

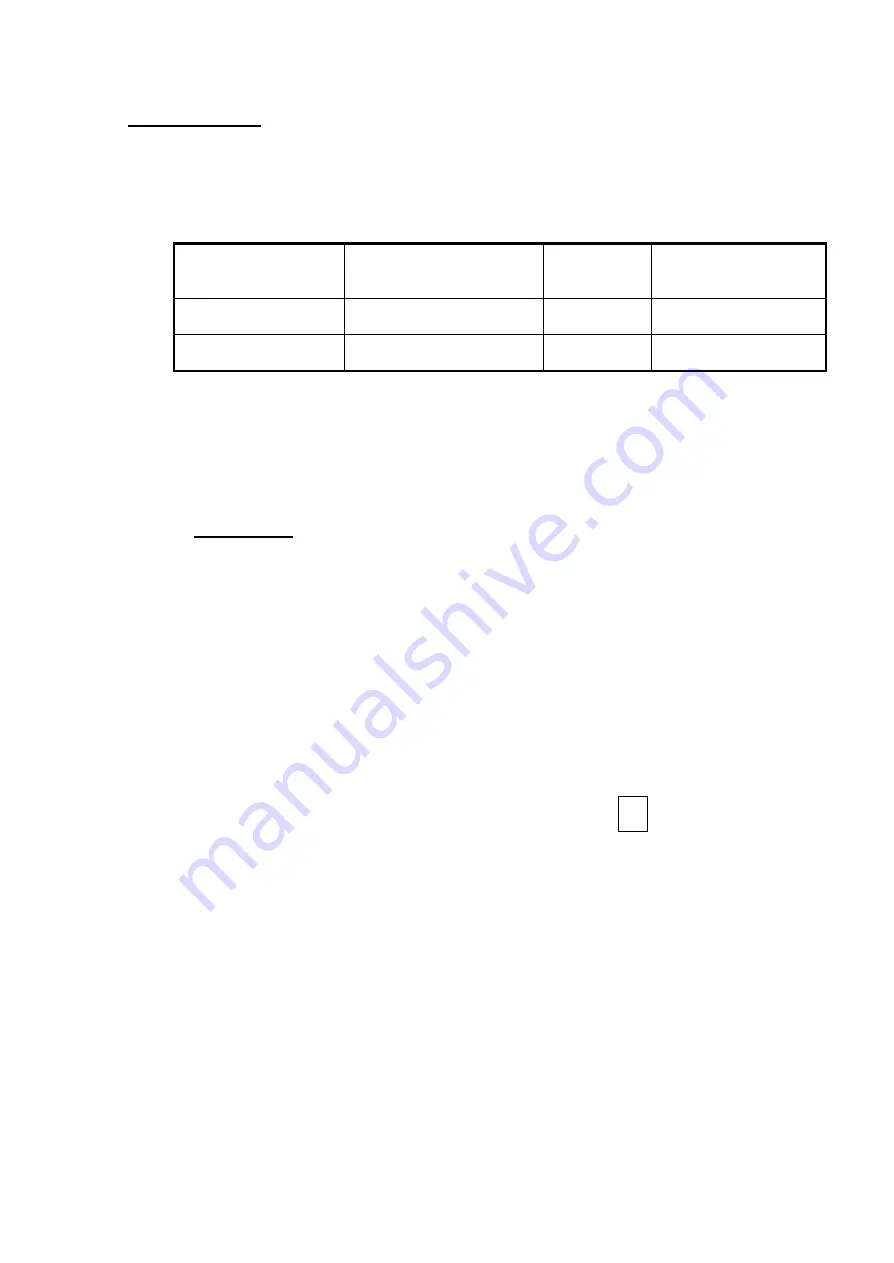

Item

Model

Sectional area of

power cable (mm2)

Air switch

(A)

Sectional area of

ground cable

(mm2)

INTIG 402 PULSE

≥2.5

40

≥25

6.Installation :

a.

The power supply of this machine is 3~ 415

V 50/60HZ, user should prepare the switchboard

and install the air switch (breaker) and ground cable. Connect the green-yellow wire of the

three-phase input cable to the grounding wire on the switchboard reliably according to the

below table:

b. - Connect the argon gas to the air inlet through reducing valve (Use

Ф6 air hose);

c. - When work as Tig, connect

“+” terminal to work-piece firmly; when work as MMA, connect

the “+” terminal according to different electrode;

d.

- Welding torch connection: Air cooling torch: connect the torch gas hose withthe

“Gas outlet

“on the welding machine, connect the torch control plug with the “Torch Switch“on the

welding machine, connect the main cable with

“-” terminal on the welding machine;

7. Operation :

e. Turn on the power switch, the welding machine start to check by itself, the digital meters

and indicators on panel lights on together for 1.5 seconds and lights off 0.5 seconds, then

display normally;

f. - Press the torch trigger switch & adjust the argon gas flow according to different welding

technology.

g. - Set the

“pulse on/off” according to different welding technology, press the “Pulse current”

key to do that. If choose

“pulse off”, set the welding current by adjusting the encoder; if

choose

“pulse on”, set the “peak current”, “PWM ratio”, “Pulse frequency” and “base

curre

nt”, press left/right selection key to choose the parameters need to be set;

h. - Set the

“gas pre-flow time”, “arc starting current”, “Up-slope time”, “down- slope

time

”,”crater current” and “gas post-flow time” according to different welding technology;

i. Welding operation:

i. Two steps: take the tungsten electrode close to the work-piece about 1~3mm,

press the welding torch switch without loosen, it start

B

s weld normally after current

up-slope, when finish welding, loosen the welding torch switch, the current down-

slope to crater current. After welding, please do

n’t take away the welding torch at

once, should wait the gas post-flow time finish, to protect the weld crater and

tungsten electrode;

ii. Four steps: take the tungsten electrode close to the work-piece about 1~3mm,

press the welding torch switch without loosen, after arc striking, find the welding

position, then loosen the welding torch switch, the welding current will increase to

the set current, it starts weld normally , when finish welding, press the welding

torch switch again, the current down-slope to crater current, loosen the torch

switch, arc stop and the welding finish. After welding, please do

n’t take away the

welding torch at once, should wait the gas post-flow time finish, to protect the weld

crater and tungsten electrode

j. MMA: connect the work-

piece too “+’”-” according to different welding technology; after

connecting the ground cable and electrode holder, set the welding current/arc force

current/hot starting current according to electrode

diameter; before welding, the welding machine output 18V

~

20V DC voltage, when the

instant moment that electrode touch the work-piece, the welding

machine output welding current and start the normal welding, after arc stop, the open

circuit voltage will remain 1 second.