2.3.2. Filling/Draining the Heating System

After completing installation of the boiler, a ball valve shall be fitted to the

heating system to provide supply from the city line to the closed circuit

heating system. Open this valve until the Manometer pressure reaches 1-1.5

bar, then close the Filling Valve by turning it clockwise, and Vent the air in

the radiator with air vent valves.

The discharge of the safety valve of the boiler must be connected to a

discharge hopper. Otherwise, the manufacturer shall not be responsible

for drainage of water into to the installation place when the safety valve is

enabled.

2.3.3. Drainage of the Condensate Water

The appliance shall be connected to the drainage water network through pipes

with minimum Ø 24 mm diameter, and resistant to

acidic condensate water. The connection of the appliance to the drainage water

line shall be performed in the way to prevent freezing of the water contained

therein. It must be ensured before starting up the appliance that the condensate

water has been drained properly; then check that the flusher is filled with

condensation water (2.2.9). In addition, the installation and all connections must

comply with the specifications, national and local regulations on discharge of

waste water.

2.3.4. Circulation Pump (Optional)

As Enerwa Plus H boilers are supplied without pump, a pump shall be used to

provide the required flow rate for the radiator heating system depending on

the critical line pressure loss. Warmhaus recommends the pump complying

with the European Energy Efficiency Directives (ErP) given in Figure 38 which

is provided as optional , in order to achieve a good performance and energy

saving

2.3.5. Filling the flusher for Condensation Line

After the wall mounting operation of condensing boiler, electrical

connections, radiator lines, hot tap water connections and condensation

water drainage line are completed, condensation flusher shall be filled with

water (Figure 8).

• The heating installation must be washed and cleared off dirt before

filling!

Figure 7

Combi bottled gas connection

LPG

LPG

Ball Valve

COLLECTOR

370 mmSS

2 kg

Hood

12 kg or

24 kg

LPG TUBE

High Temperature

Circuit

Condensate

Drainage

Gas

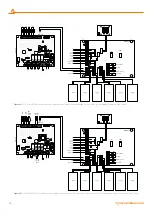

Figure 8

Connection Diagram of Single Boiler and 1 High Temperature Circuit

Figure 9

Filling the condensation flusher

2.3. HYDRAULIC INSTALLATION RULES

2.3.1. Heating System Water

In order to prevent invalidity of appliance warranty prior to making

boiler connections, clean possible residues found in main heat

exchangers (pipes, heater assembly, etc.) with dissolvent or equal

substances, otherwise they will negatively affect functioning of the boiler.

Equivalent materials in order to avoid cancellation of the warranty,

otherwise proper operation of the boiler will be affected negatively. In order

to prevent lime scale in the radiator follow rules envisaged by standards

regarding domestic hot water and radiator installations.

10

warmhaus.com