D1WWTD02E

15

Service Manual

DPC130X

Do not carry out maintenance operations on the control valve when an explosive atmosphere is present and the control valve

surface temperature is outside the environmental temperature range as specified before.

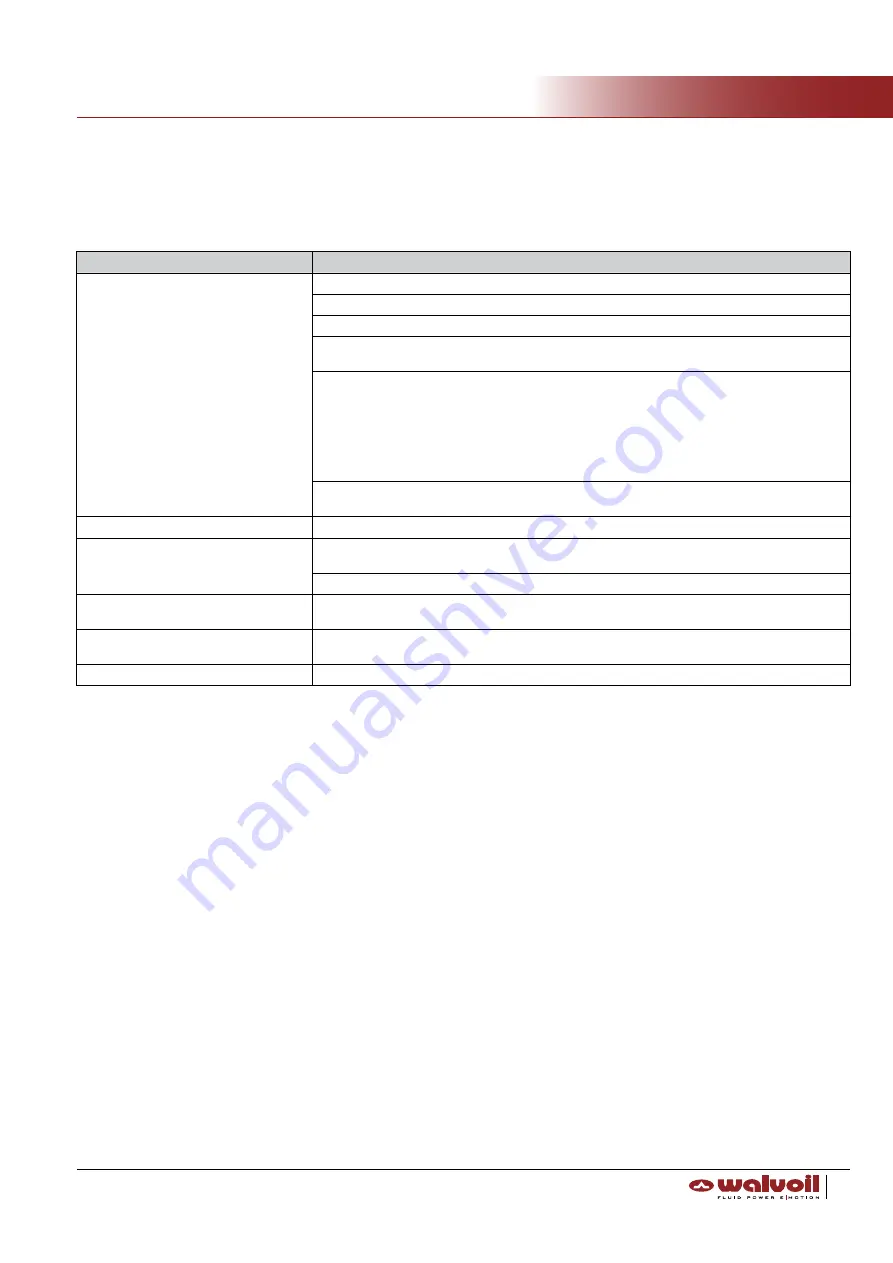

It is advisable to periodically check the parts shown in the table below.

___________________________________________________________________________

Standard maintenance rules

______________________________________________________________________________________________________

Disposal

Reference

Item to be checked

General installation

Verify valve is correctly and safely fixed in its seat

Check electric connector and wire condition and wear

Clean the valve carefully, avoiding direct jet, especially on electric parts and connections

In order to prevent rust, dry the valve after cleaning, avoiding scratching and damaging external

surfaces

Periodically check the tightening of:

- Tie rods

- Lever box

- Control kit screws

- Unloading screw

- Electrohydraulic valve screws

- Hydraulic fittings

Constantly check oil contamination status and plant filter condition. Contamination may bring to

several malfunctions

Body

Check presence of excessive rust and corrosion and replace parts or complete valve if needed

Spool

Check presence of scratch, rust and corrosion. It may bring to seals damage or spool sticking. Re-

place parts if needed

Apply grease on spring, lever or positioning kits if the spool operation is not sliding

Sealing

Check and replace any possible hardened, de-formed or damaged O-ring. Check and replace the

O-ring also in case its surface is dirty or shows particles.

LS Valve and Auxiliary Valves

Periodically check pressure setting values, if not correct adjust relief valves and safely lock the nut

at appropriate torque

Electric components

Please refer to attached service manual of these components

When the control valve has to be disposed, first drain the hydraulic fluid completely and dispose of it as industrial waste.