Safety

LXG520R

Grapple

Safety

9

2.4.1 Equipment Safety Guidelines

A few seconds of thought and a careful approach to handling

equipment can prevent accidents.

•

Replace safety or instruction signs (decals) that are not

readable or missing. For locations and explanations, see

.

•

Do not modify the equipment in any way. Unauthorized

modifications may affect the integrity of the machine

or the ability of the machine to perform as designed.

Modifications can impair safety or function. They can affect

the life of the equipment and void the warranty.

•

Make sure the machine is correctly stationed, adjusted, and

in good operating condition.

•

Never exceed the limitations of the machine. If its ability to

do the job, or to do it safely is in question–

STOP!

•

Protective cab shields must be provided on a log loader

unless the absence of shields does not pose a hazard to the

operator.

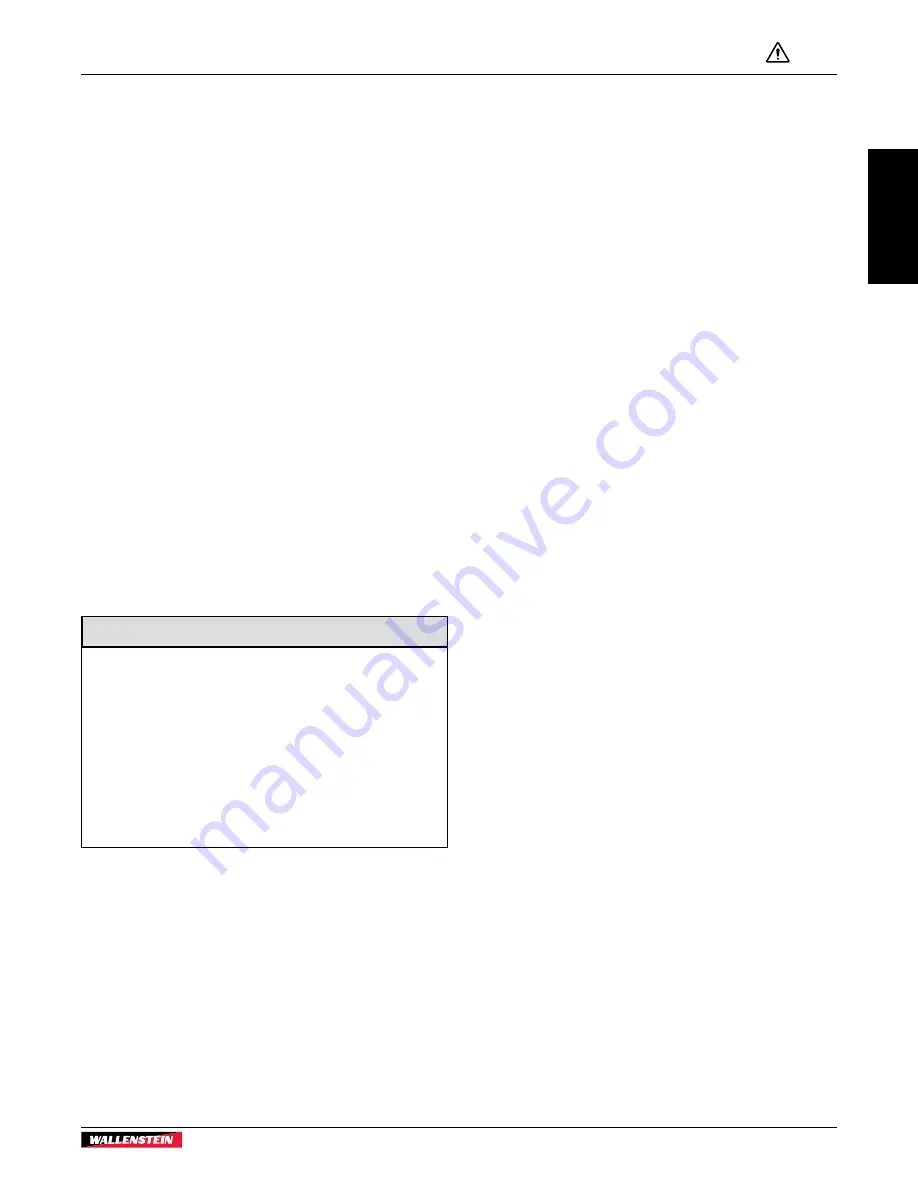

2.4.2 Safe Condition

References are made to

safe condition

throughout this manual.

Safe condition means putting the machine in a state that makes

it safe to service or maintain.

Before starting any service or maintenance, complete the

following:

SAFE CONDITION

1.

Remove material from the grapple.

2.

Lower the grapple to ground.

3.

Turn off the excavator engine.

4.

Engage the hydraulic control lockout device.

5.

Turn off the main hydraulic switch.

6.

Move the hydraulic controls to make sure that there is no

movement.

2.5 Create a Safe Work Site

For more information, see

2.5.1 Designated Safe Area

A

Safe Area

must be designated for workers who are on foot

and in close proximity to the equipment.

•

The boundaries of a designated Safe Area must be

communicated to all workers within and in close proximity

to the Work Zone.

•

No equipment should enter into or proceed through a Safe

Area unless—

-

The equipment operator first obtains permission in a

clear and unmistakable manner from all of the workers

in that safe work area or from the supervisor of those

workers, and

-

Those workers take a safe position.

2.5.2 Work Zone Arrangement

•

A

Work Zone

includes any area where work with this

grapple is done, but does not include the traveled portion

of a road unless that portion of the road is being used as a

landing.

•

Work being done in a Work Zone in a forestry operation

must be planned and the work area must be located,

constructed, maintained, and operated to ensure that:

-

Logs can be moved safely in the area.

-

Log piles and equipment used to handle the logs do not

become unstable or otherwise create a hazard.

-

Workers are able to work in locations clear of moving

logs and equipment.

-

Workers are not exposed to incoming or runaway logs

or other debris.

-

The area is kept free from buildup of bark and other

debris to the extent that it would pose a risk to workers.

-

An effective method of dust control is used and

maintained.

•

Log piles must, to the extent practicable, be located on

stable and relatively level ground.

•

Log piles must not be higher than the safe operating reach

of the excavator being used to handle the logs.