FX85, FX110, FX140

PTO Skidding Winch

Service and Maintenance

41

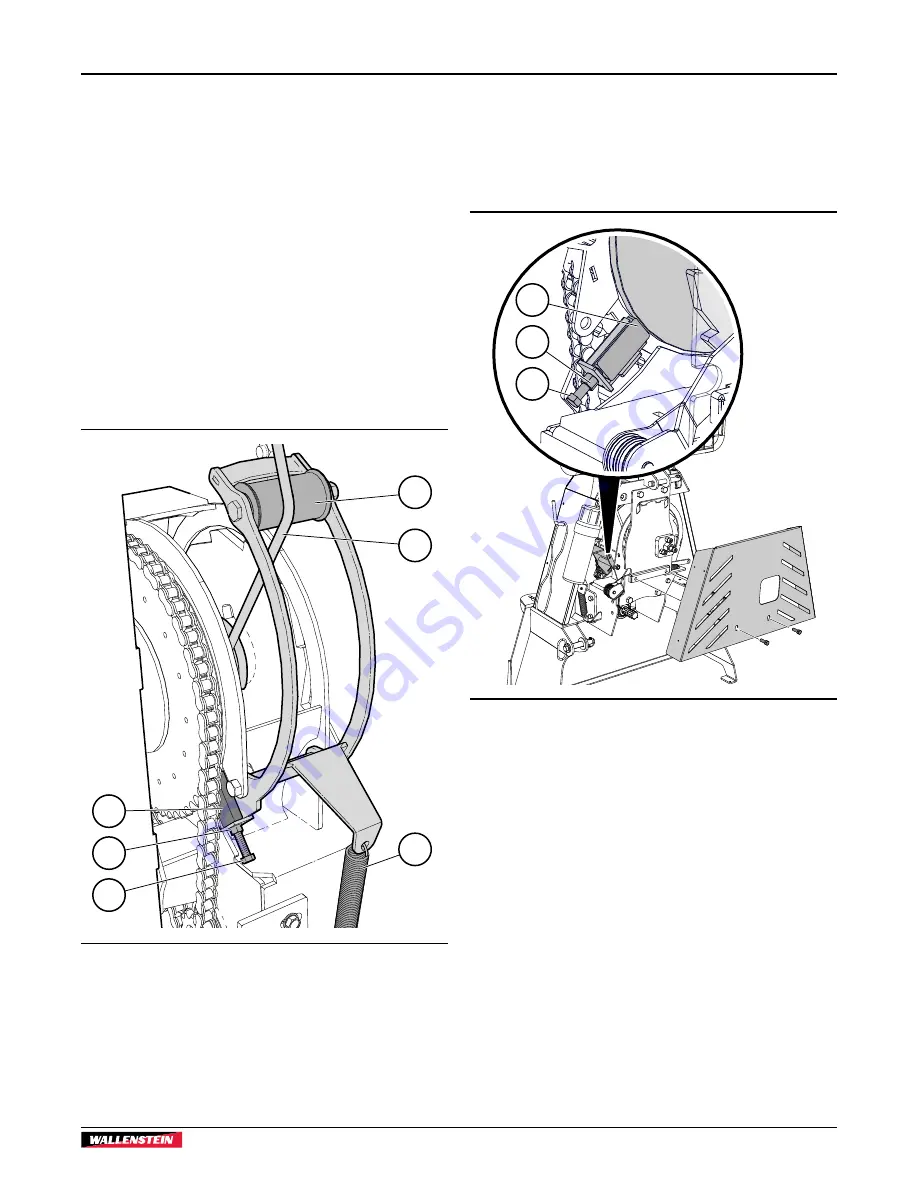

7.7 Drum Brake Adjustment

7.7.1 Winch Drum Brake Operation

The winch brake stops the drum from turning when there is no

tension on the rope and the drum lock is not engaged. The brake

must be set to hold the drum from freewheeling when the rope

is not being pulled out to avoid tangling.

As the rope is spooled off the drum, it is routed over the top

of the brake assembly arm. The force of spooling the rope off

the drum, moves the arm to release the brake. When the rope

is no longer being spooled on, the spring pulls the arm back

and engages the brake. The brake must be set to stop the drum

from freewheeling when the rope is not being pulled out to avoid

tangling.

Remove lower protective shield from the front side of the winch

to access brake adjustment.

00606

1

2

3

4

5

6

Fig. 52 –

Winch Brake

1. Adjuster Bolt

2. Jam Nut

3. Drum Brake Block

4. Brake Arm Cable Roller

5. Cable

6. Spring

7.7.2 Procedure

1.

Loosen jam nut (2) on adjustment bolt.

2.

Tighten the adjustment bolt (1) until the brake block (3) just

contacts the drum.

3.

Tighten jam nut.

00607

1

2

3

Fig. 53 –

Winch brake Adjust

1. Adjuster Bolt

2. Jam Nut

3. Drum Brake Block

Summary of Contents for FX Series

Page 1: ...OPERATOR S MANUAL PTO driven Log Skidding Winch FX Series Part Number Z97090_En Rev May 2021 ...

Page 54: ......

Page 55: ......

Page 56: ...www wallensteinequipment com ...