Service and Maintenance

FX85, FX110, FX140

PTO Skidding Winch

40

7.5 Drive Chain Tension

The winch is designed with a roller chain to transmit the power

between the PTO input and the clutch / winch. The chain tension

is automatically set through a spring-loaded sliding tensioner.

The chain tensioning system is designed with an internal

compression spring to set maximum chain tension during

operation. No adjustment is required.

00603

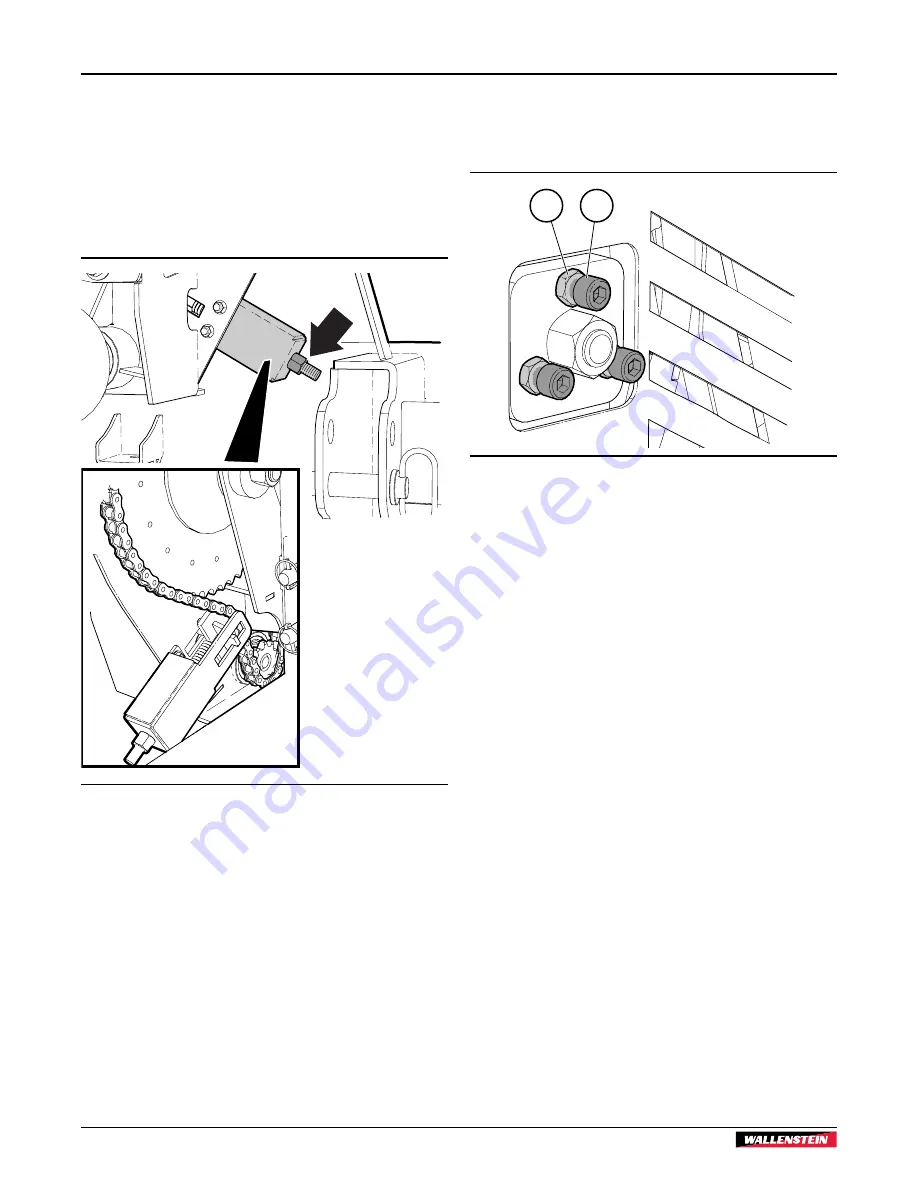

Fig. 50 –

Chain Tensioner

7.5.1 Drive Chain Replacement

If replacing the roller chain, follow this procedure to release

tension on the chain:

1.

Turn in (tighten) the adjusting nut on tension bolt until chain

tension is released (minimum chain tension).

2.

Remove the old chain and install the new chain.

3.

To set the chain to maximum tension, turn out the adjusting

nut on tension bolt within 1/4" (6 mm) from end of tension

bolt.

7.6 Clutch Adjustment

Adjust the clutch using the following method if it begins to slip

or goes out of adjustment.

00604

1

2

Fig. 51 –

Clutch Adjustment

1. Jam Nut

2. Socket Head Capscrew

Procedure

1.

Loosen the three jam nuts on the front side of the winch.

2.

Turn socket head capscrews inward by hand until they just

contact the pressure plates.

3.

Tighten bolts equally until the desired amount of free play

is felt on clutch lever. Pull on rope to feel free play in clutch

and adjust as required.

4.

Tighten jam nuts.

5.

Check clutch setting before resuming work. Start PTO and

check for drag on the clutch.

Drag can cause the winch rope to inch in without the rope being

pulled. If the rope is inching in with the clutch disengaged, go

through the above steps again to readjust.

Summary of Contents for FX Series

Page 1: ...OPERATOR S MANUAL PTO driven Log Skidding Winch FX Series Part Number Z97090_En Rev May 2021 ...

Page 54: ......

Page 55: ......

Page 56: ...www wallensteinequipment com ...