9.8 Ledger Knife Maintenance

WARNING!

Machine shown with shields removed for

illustrative purposes only. Never operate

machine with shields removed.

W001

Inspect the ledger knife for sharpness before each use.

Sharpen the ledger knife after every 50 hours of operation.

Material in the chipper is sheared off at the stationary ledger

knife when the rotor knives pass by.

The ledger knife can be turned or rotated, so that all four edges

on the long sides can be used. When the edge facing the rotor

knives becomes rounded over, remove the ledger knife, and then

install it with a different long edge facing the rotor knives.

When all four edges of the knife are rounded over, remove the

knife and sharpen it.

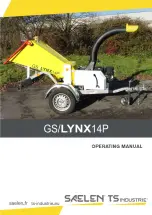

9.8.1 Sharpen the Ledger Knife

If the ledger knife has been sharpened on all corners and it is

no longer possible to set the correct clearance with the rotor

knives, replace the ledger knife.

1.

Sharpen both long edges of the knife at a 90° angle.

2.

Install the ledger knife and use the ledger knife clearance

gauge to set the correct clearance.

3.

Use a calibrated torque wrench to tighten the bolts to

33 lbf•ft (45 N•m)

.

01098

90°

90°

Fig. 34 –

Sharpen a ledger knife

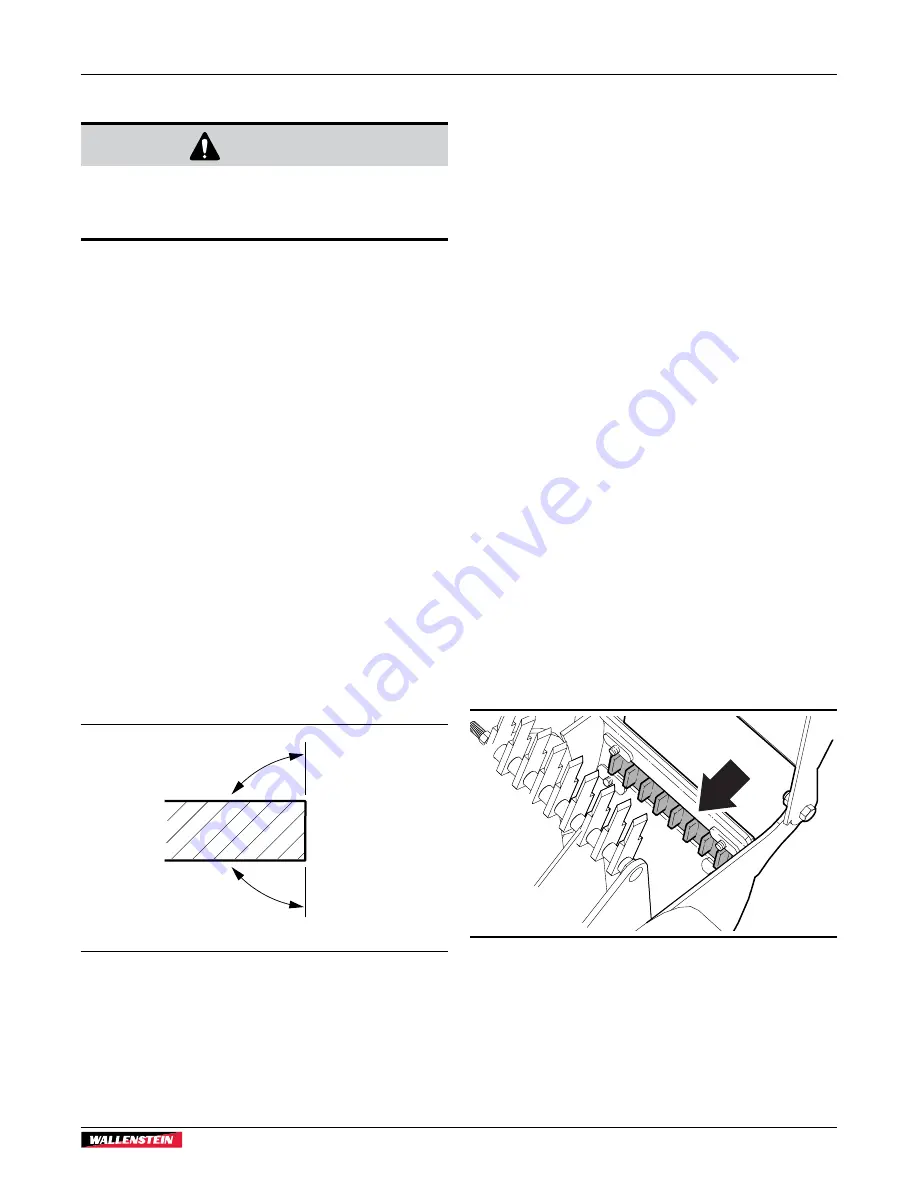

9.8.2 Set the Ledger Knife Clearance

1.

Loosen the ledger knife bolts.

2.

Move the ledger knife forward (toward the rotor knives).

Snug the bolts by hand.

3.

Turn the rotor until one of the rotor knives is directly aligned

with the ledger knife.

4.

Use the ledger knife clearance gauge to set the clearance

between the two knives. Tap the ledger knife toward the

rotor blade.

If a ledger knife clearance gauge is not available, set the

clearance between 1/32 and 1/16" (1 to 1-1/2 mm).

5.

Use a calibrated torque wrench to tighten the bolts to

33 lbf•ft (45 N•m)

.

9.9 Chop Block Maintenance

Inspect the chop block for wear or damage before each use.

Rotate or replace the chop block after every 50 hours of

operation.

The chop block is bolted to the bottom of the rotor housing. The

purpose of the chop block is to help the shredder knives break

material into smaller pieces and turn it into mulch.

Inspect the chop block for damage, such as gouges, and bent or

missing teeth.

•

If the chop block teeth are worn on one side, turn the chop

block around and install it the opposite way.

•

If both sides of the teeth are worn or the chop block is

damaged, replace it.

01099

Fig. 35 –

Chop block in the rotor housing

BXMT3213

Trailer Chipper / Shredder

Service and Maintenance

43