BXC34

Cart Chipper

Service and Maintenance

33

01196

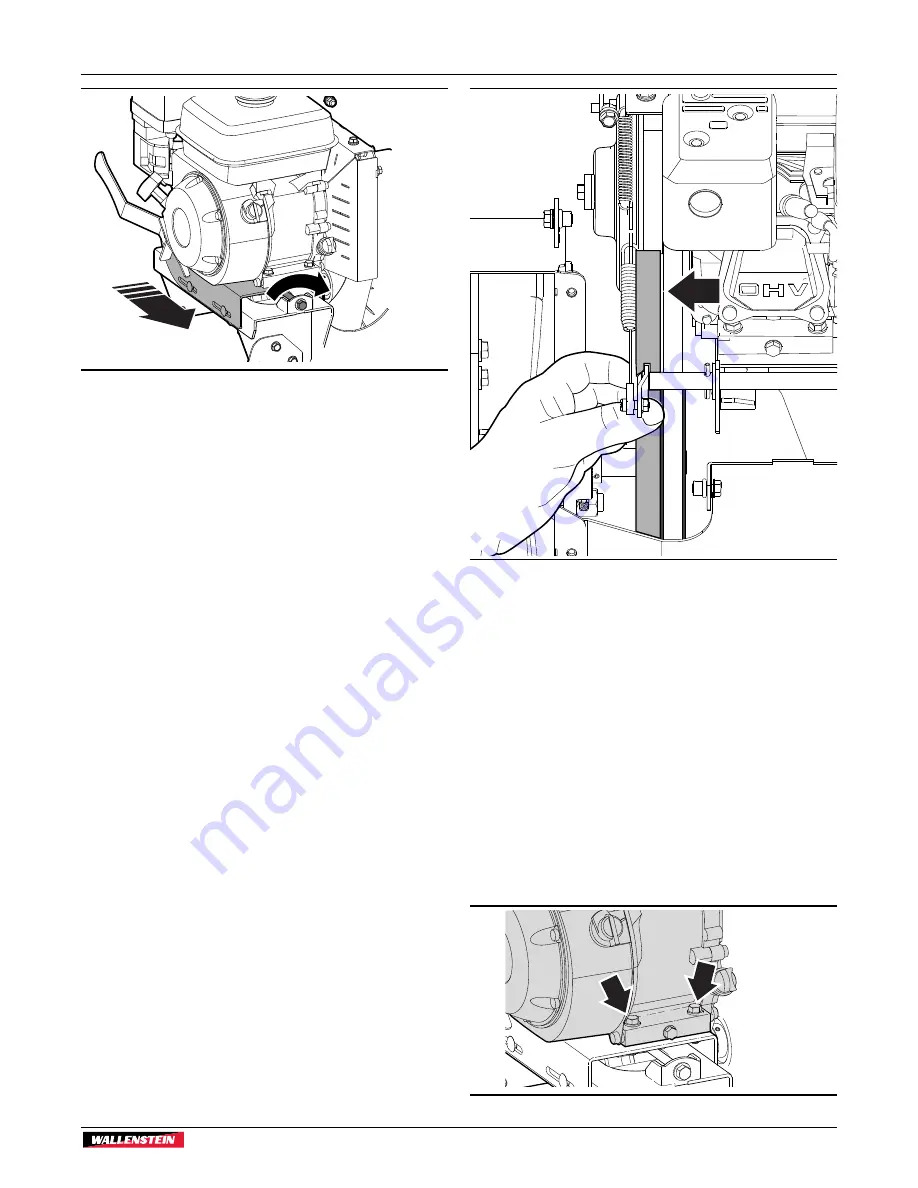

Fig. 33 –

Drive belt Tension Adjustment

3.

Pull the engine back to snug up the belt, then tighten the

bolts on the opposite side from the belt.

4.

Turn the belt tension adjuster bolt clockwise to tighten the

belt. Turn it counterclockwise to loosen the belt. Check and

adjust belt tension accordingly. Be aware of belt alignment

when adjusting belt tension. See

Drive Belt Alignment

to

follow.

5.

Recheck belt tension. Once set correctly, tighten up all four

engine mount bolts. Re-install the belt shield.

6.

Recheck belt tension after 10 hours of operation.

7.5.2 Drive Belt Alignment

Observe drive belt alignment every 8 hours of operation.

For accurate measurement use a laser alignment tool. If one is

not available, the following method can be used.

The maximum misalignment is 1/32" (1 mm).

Place a straight edge along the back face of the rotor sheave

and compare the gap along the belt. The gap between the drive

belt along the length of the straight edge must be equal. Adjust

accordingly.

01197

Fig. 34 –

Sheave Alignment

If the gap is not even along the length of the belt, determine

whether the engine is square to the chipper frame. It may also

be that the rotor sheave has moved in or out on the shaft. Belt

misalignment can be corrected two different ways:

-

Engine mount alignment

-

Rotor sheave alignment

Engine Mount Alignment

After changing the drive belt, the angle of the engine mount

could shift resulting in poor belt alignment.

1.

First, make sure the bolts fastening the engine to the mount

are tight. Make sure the engine is square to the base and

the bolts are properly torqued.

01198

Fig. 35 –

Engine Mount Bolts