Maintenance Instructions

LUBRICATION

44

Mower Deck Gearbox Lubrication

On gear driven decks, the mower deck gearboxes

(tee gearbox and blade drive gearboxes) are con-

nected as a unitized assembly, and oil flows freely

between them. The gearboxes are permanently lu-

bricated (oil filled) and sealed requiring no sched-

uled lubrication. However, the gearbox oil seals

should be checked

every 25 hours

for indication of

an oil leak;

particularly the lower seals

on the

blade drive gearboxes should be inspected, since

they operate in a dirty environment. If an oil leak is

noted, replace the oil seal and relubricate the gear-

box assembly as follows:

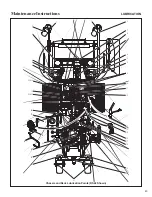

1. Remove gearbox cover (footrest). Deck orien-

tation should be the normal operating position.

Blade Drive

Gearboxes

Tee

Gearbox

Mower Deck Gearboxes

(Shown with Gearbox Cover

Removed for Clarity)

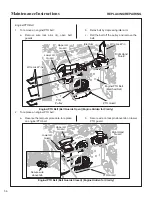

2. Clean the area around the individual gearbox

cover plates to prevent contaminants from en-

tering the gearcase.

3. Remove the screws securing the cover plates

on the blade drive gearboxes.

4. Check the level of lubricant in the gearboxes. If

the lubricant is low, add SAE E.P. (Extreme

Pressure) 80W-90 (API GL-5) gear lube until

the oil level is up to (submerges) the horizontal

shaft in the gearbox (shaft parallel to cover

plate).

NOTE:

In case the gearboxes are completely

drained of oil, approximately 5 fl. oz. (15 cl) of oil

per gearbox is required to refill the gear drive

assembly.

NOTE:

Since the gearboxes are connected as

a unit by connector tubes, it is necessary to add

oil slowly. Allow a few minutes after adding oil

for the oil to flow throughout the assembly and

the oil level to stabilize before reassembly.

IMPORTANT:

DO NOT

overfill the deck gear-

boxes. The gearbox assembly is not vented,

and overfilling with oil will cause excessive pres-

sure and result in oil leaks.

5. Check condition of the cover gasket and replace

if worn or damaged. Reinstall gearbox cover

plates; torque screws to 24 lb

·

in. (3 N

·

m).

Mower Deck Spindle Lubrication

For belt driven decks, lubricate each deck spindle

grease fitting

every 25 hours.

Use SAE general

purpose lithium or molybdenum base grease for

grease fittings.

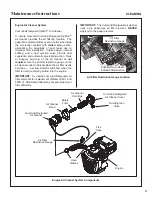

Transaxle Fluid Level

•

The transaxle oil lubrication is SAE 20W-50 (API

Service Class SL or higher) engine oil.

•

Inspect both transaxle cases and hoses

after ev-

ery 100 hours

of operation for visible leaks.

•

The fluid level of each transaxle can be checked

visually by looking at the fluid level in the expansion

reservoir. When the transaxles are cold, the fluid

level in the expansion reservoir should be between

1/4 in. and 1/2 in. (0.64 cm and 1.27 cm).

Reservoir Cap

Cold Level

Expansion Reservoir Location

Summary of Contents for B18

Page 73: ...69 Operator s Notes...

Page 74: ...70 Operator s Notes...