9

Assembly Instructions

The Walker Lawn Dethatcher will effectively dislodge

excessive thatch from your lawn. Thatch is a layer of

stems, clippings, runners, roots, and leaves that have

not decayed. Excessive thatch prevents air, water,

and fertilizer from reaching the roots. These instruc-

tions will help ensure proper assembly and operation.

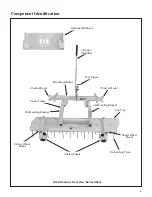

1. Attach the caster wheel mounts to the tine tray as

shown in

Install Caster Wheels

illustration. In-

stall the caster fork/wheel assembly into the cast-

er wheel mount as shown. Be sure to install the

shock washer and three (3) spacers before in-

stalling the caster fork. Install the remaining three

(3) spacers at the top of the caster fork and install

the lynch pin. Use this as a starting point for the

spacer location.

7

20

20

F255

F316

F316

F255

20

F434

F017

21

21

23

580

9-2

25

F009

Install Caster Wheels

(Carrier Frame and Tray Mounting Brackets

Removed for Clarity)

2. Attach the tines to the tine tray finger tight, as

shown in the

Install Dethatching Tines

illustra-

tion. It is important to be sure the loop between

the tine coils nests around the hardware on the

tine tray. After all the tines are installed, tighten

the tine mounting hardware.

3. Insert safety rods through the coils of the tines as

shown in the

Install Dethatching Tines

illustra-

tion. Secure by bending the end of the rod 1-1/2

in. to 2 in. from the end to prevent them from slip-

ping back through the tines. The safety rod must

be free to move slightly from side to side.

F571

Dethatching Tine

Tine Retainer Clip

F170

F009

Safety Rod

5809-2

Install Dethatching Tines

(Caster Wheel Assembly Removed for Clarity)

WARNING

Failure to install the safety rods can result

in personal injury if a tine should disengage

from the tine tray.

4. Install the foot trigger as shown in

Foot Trigger

photo using the 5/16-18 x 1-3/4 Hex Bolt (F316),

5/16 x 1 x 7/64 Flat Washer (F170), Washer

(F060) and 5/16-18 ESNA Nut (F020). Foot

trigger should move freely after tightening nut.

Foot Trigger