GB

18

W 867 E

This appliance is not intended for use by persons (including children) with

g)

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

4. Careful Handling and Use of Power Tools

Do not overload the tool. Use the power tool designed for the work that you

a)

are doing.

You work better and safer in the specified performance range if you use

the suitable power tool.

Do not use power tools whose switch is defective.

b)

A power tool that cannot be

switched on or off is dangerous and has to be repaired.

Remove the plug from the socket before carrying out tool settings, changing

c)

accessories or putting the tool away.

This precautionary measure prevents

unintentional starting of the tool.

Store unused power tools so that they are inaccessible to children. Donot

d)

let persons use the tool who are not familiar with it or who have not read

these instructions.

Power tools are dangerous when they are used by inexperienced

persons.

Take proper care of your tools. Check whether the moving parts

e)

functiontrouble-free and do not jam, whether parts are broken or damaged

so that the tool function is impaired. Have damaged parts repaired before

using the tool.

Many accidents have their origin in power tools that have been

maintained badly.

Use the power tool, accessories, insert tools, etc. in accordance with these

f)

instructions and in a fashion specified for this special tool type. Take the

working conditions and the activity to be carried out into consideration.

The

use of power tools for purposes other than the intended ones can lead to dangerous

situations.

5. Service

Have your tool repaired only by qualified specialist personnel and only with

a)

original spare parts.

This ensures that the tool safety is maintained.

If the supply cord is damaged, it must be replaced by the manufacturer or it’s

b)

service agent or a similarly qualified person in order to avoid a safety hazard.

Safety Instructions for Spray Guns

ATTENTION! EXPLOSION HAZARD!

Do not store materials with a flash point below 21°C in the basic device!

Only store materials in the basic device in containers that close airtight!

Remove any material that may have leaked into the basic device immediately

and allow the device to dry completely before using it! Do not store materials

contained solvents in the basic device during operation!

Summary of Contents for W 867 E

Page 1: ...2 ans de garantie 2 jaar garantie 2 years Guarantee 2 Jahre Garantie W 867 E D GB F NL ...

Page 2: ...W 867 E 10 24 25 26 9 12 11 18 23 22 27 21 29 28 7 8 6 4 5 3 19 1 2 13 14 17 16 15 20 30 31 ...

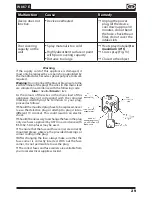

Page 3: ...W 867 E f e A B d c ...

Page 4: ...W 867 E h j g i 2 2 1 1 3 A C A B C 20 30 cm B ...

Page 5: ...6 19 11B 8 9 7 17 13 14 15 11A 1 18 4 3 2 12 C 11B 11A 11 10 5 20 21 22 W 867 E k ...

Page 6: ...W 867 E l D 1 15 16 30 31 45 46 60 62 GB NL F ...