13

VERSION 02/2019

ORDER NUMBER DOC 2397374

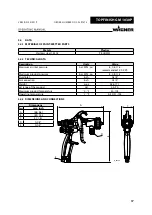

TOPFINISH GM 1030P

4.2.2 SAFE HANDLING OF WAGNER SPRAY DEVICES

Hazard due to injection of lacquer or flushing agent into the skin!

The spray jet is under pressure and can cause dangerous injuries. Avoid injection of

lacquer or flushing agents:

Never point the spray gun at people.

Never reach into the spray jet.

Before any work on the device, in the event of work interruptions and malfunctions:

– Switch off the energy/compressed air supply.

– Relieve the pressure from the spray gun and device.

– Disconnect the control unit from the mains.

– In the event of functional faults: remedy the fault as described in

Chapter „9 Troubleshooting and Rectification“.

If needed, the liquid ejection devices must be checked by experts (e.g., WAGNER

service technician) at least every 12 months for their work-safe condition in

accordance with DGUV regulation 100-500 Chapter 2.29 and Chapter 2.36.

– For shut down devices, the examination can be suspended until the next start-up.

In the event of skin injuries caused by lacquer or flushing agents:

Note the lacquer or flushing agent that you have been using.

Consult a doctor immediately.

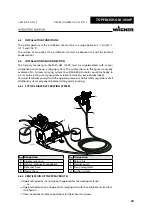

4.2.3 GROUNDING THE DEVICE

Danger due to electrostatic charge!

Explosion hazard and damage to the device.

Friction, flowing liquids and air or electrostatic coating processes create charges.

Flames or sparks can form during discharge.

Correct grounding of the entire spraying system prevents electrostatic charges.

Ensure that all devices and tanks are grounded before each spraying process.

Ground the work pieces to be coated.

Ensure that all persons inside the working area are grounded, e.g., that they are

wearing static dissipative shoes.

Wear static dissipative gloves when spraying. The grounding takes place via the

spray gun handle or the trigger.

Summary of Contents for TOPFINISH GM 1030P

Page 1: ...B_06965 TOPFINISH GM 1030P Airspray manual gun for flat and round jet nozzles Version 02 2019...

Page 2: ......

Page 26: ......

Page 51: ......