ProSpray 3.29 • 3.31

17

GB

Repairs at the unit

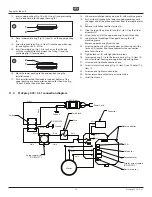

14. Unscrew lower housing (Fig. 13, Item 10) with adjusting

wrench while holding the upper housing (11) securely with a

second adjusting wrench.

15. Remove bearing ring (13) and O-ring (12).

16. Screw out outlet valve housing (14) from the piston (15) with

3/8 inch hexagon socket head wrench.

17. Remove the upper seal (16), upper ball guide (17), outlet valve

ball (18), washer (19) and outlet valve seating (20).

18. Clean all the parts with the corresponding cleaning agent.

Check outlet valve housing (14), outlet valve seat (20), outlet

valve ball (18) and upper ball guide (17) for wear and replace

parts if necessary. If the worn outlet valve seat (20) is unused

on one side, install it the other way around.

19. Carry out installation in the reverse order.

Lubricate O-ring (12) with machine grease and ensure proper

seating in the lower housing (10).

11

15

16

17

18

19

20

14

12

13

10

11.3 Packings

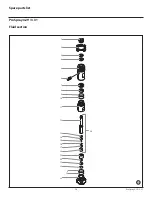

1. Remove inlet valve housing in accordance with the steps in

Chapter 11.2, Page 16.

2. It is not necessary to remove the outlet valve.

3. Loosen lock nut (Fig. 14, Item 5) counterclockwise with light

blows from a hammer.

4. Unscrew upper housing (6) counterclockwise from the gear

unit housing.

5. Clamp upper housing (6) at the wrench surfaces vertically in a

vice.

Attention

Do not tighten vice excessively to prevent crushing.

6. Screw out threaded joint (7).

7. Slide the piston rod (4) forward until the piston is out of the

T-slot (2) on the slider assembly (3).

8. Push piston (4) downward out of the upper housing (6). Check

piston for wear and replace if necessary.

9. Remove upper packing (8) and lower packing (9) from the

upper housing (6).

Attention

Do not damage inside of upper housing.

3

1

2

5

7

10

8

9

6

4

11

10. Remove the transportation devices from the upper and lower

packings. (The transportation device from the upper packing

is required for installation of the piston.)

11. Lubricate upper packing (8) and lower packing (9) with

machine grease.