Introduction

2

0241891

– PI-P1 / PI-F1

08/2008

Powder injector PI - P1

Article No. 0241621

Powder injector PI - F1

Article No. 0241622

28 m

m

110 m

m

F

A

S

D

0241621_01b

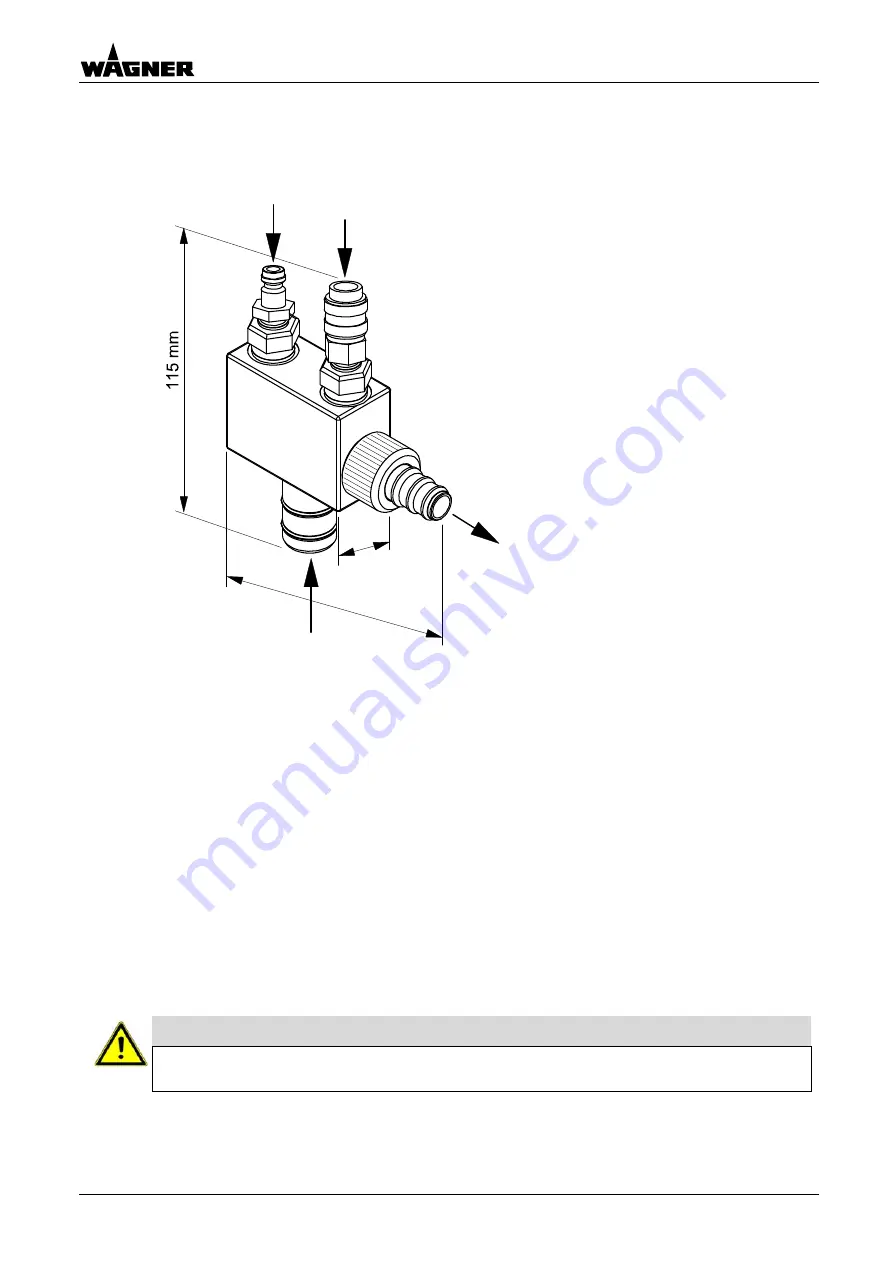

A

Powder inlet from powder container

F

Feed air inlet

D

Dosage air inlet

S

Powder/air mixture outlet to gun

The switched air mode

:

No powder is fed to

A

if the feed air

F

is

switched off and, simultaneously, the

dosage air quantity

D

is increased to

maximum level.

No new powder

A

is fed to the spray

gun, while the powder feed hose

S

is

regularly purged with dosage air. The

powder flow

A

starts immediately as

soon as the feed air is switched on

again and the dosage air is switched to

normal quantity.

The powder injector is used for powder feeding in manual as well as automatic powder coating

systems. In addition to this, the powder injector is also ideally suitable for switching mode.

All types of coating powder can be processed with the injector.

A choice of two powder injectors is available:

•

powder injector

PI-P1

and

•

powder injector

PI-F1

The

PI-P1

powder injector is connected to control units, which regulate air pressure.

The

PI-F1

powder injector, on the other hand, is connected to control units which control the

compressed air flow rate, making this powder injector suitable for applications involving control

units with

AFC technology

(flow rate control) and purging air mode for powder flow.

Both powder injectors can be operated with the following control units:

•

powder injector

PI-P1

with

EPG 2008/EPG Prima

or

PrimaTech

•

powder injector

PI-F1

with

EPG-D1

or

ProfiTech

Caution

The maximum temperature

should not exceed 35 °C / 95 °F

. Otherwise it cannot be

ensured that the powder output quantity of the HiCoat-ED Pump can be reached.