2 3

Control Pro 350 Extra Cart

GB

Unclogging the Spray nozzle

If the spray pattern becomes distorted or stops completely while the gun is triggered, follow these steps.

Danger

Do not attempt to unclog or clean the nozzle with your inger. High pressure luid can cause injection injury.

1. Release the trigger and secure the gun. Rotate the reversible nozzle arrow 180º so that the point of the arrow is toward the

rear of the gun. (Fig. 18).

i

Under pressure, the nozzle may be very diicult to turn. Turn the switch to the PRIME position (vertical) and pull the

trigger. This will relieve pressure and the tip will turn more easily.

2. Turn the switch to the SPRAY position (horizontal).

3. Unlock the gun and squeeze the trigger, pointing the gun at a scrap piece of wood or cardboard. This allows pressure in the spray

hose to blow out the obstruction. When the nozzle is clean, material will come out in a straight, high pressure stream.

4. Release the trigger and secure the gun. Reverse the nozzle so the arrow points forward again. Unlock the gun and resume

spraying.

i

The HEA Filter Set keeps nozzle blockages to a minimum (see “HEA Filter Set”).

HEA Filter Set

Assembly

Danger

The gun and high-pressure hose must be de-pressurised before

the ilter set is installed / removed.

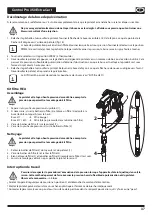

1. Disconnect the high-pressure hose from the gun (1).

2. If necessary, screw on the ilter housing (2) and insert a ilter (3) appropriate

to the nozzle (the conical side (A) must point upwards).

Nozzle 311

Filter red

Nozzle 517 / 619

Filter white (pre-installed in the ilter housing)

3. Screw the ilter housing (2) to the gun (1).

4. Screw the high-pressure hose (4) irmly to the ilter housing (2).

Cleaning

Danger

The gun and high-pressure hose must be de-pressurised before

the ilter set is installed / removed.

1. Remove the ilter housing (2) from the hose (4) and the gun (1).

2. Screw on the ilter housing (2) and remove the ilter (3).

3. Thoroughly clean the ilter (3) and ilter housing (2) (if worn, replace the ilter).

4. During reassembly, take care not to lose the seal and spring.

Interruption of Work

Danger

Be sure to follow the Pressure Relief Procedure when shutting the unit of for any purpose.

This procedure relieves the pressure from the spray hose and the gun.

Watch the pressure gauge ––> 0 bar

•

Switch the device of (pressure regulator in position 0) and remove the power plug.

•

Put the spray gun in a plastic bag and seal so that it is air-tight.

•

Wet paint surface in paint container with a little water to prevent a skin from forming.

3

1

2

4

A