58

VERSION 03/2018

ORDER NUMBER DOC 2369735

7.4

WORKING

Optimal coating results

– When relative humidity of 55–65% optimal coating results are expected.

– For the required electrostatic effect the work pieces to be coated must be conductive

and grounded.

– In the case of a wood coating, optimum results are achieved with a minimum of 12%

residual moisture.

Prerequisites

Ensure that:

The regular safety checks are carried out in accordance with Chapter

,

Commissioning is carried out in accordance with Chapter

.

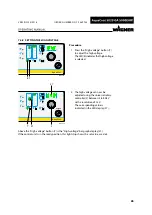

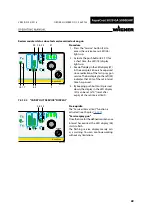

7.4.1 STARTING THE SYSTEM

AquaCoat

100

80

60

40

20

µA

80

60

40

20

10

kV

R3

R2

R1

Zerstäuberluft

Atomizing air

Mat. Druckregler

Mat. pressure reg.

Pumpe

Pump

POWER

0

1

21

15

22

1

10

9

11

3

B_03371

B_06146

VM 5020WA control unit

1. Set the main switch (1) to position 1.

During the start-up phase, the device automatically performs an internal function

test and then automatically switches to recipe 1 (15).

2. Set the desired recipe.

See Chapter

and the following for information on how to operate the control unit.

Product supply

3. Open the compressed air supply.

4. Set pump pressure regulator (9) depending upon the paint viscosity (see operating

manual of the product pressure generator).

– DD10 pump: approx. 0.2–0.6 MPa; 2–6 bar; 30–90 psi

– DD10-/ZIP52 pump with product pressure regulator: approx. 0.3–0.6 MPa; 3–6 bar;

40–90 psi

5. DD10-/ZIP52 pump with product pressure regulator:

Set product pressure regulator (10) to approx. 0.05–0.2 MPa; 0.5–2 bar; 7–30 psi

operating pressure.

6. Set external atomizing air to approx. 0.2 - 0.4 MPa; 2 - 4 bar; 30 - 60 psi.