80

VERSION 03/2018

ORDER NUMBER DOC 2369735

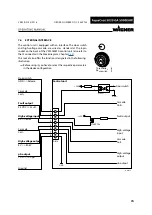

8.2.3 SAFETY CHECKS AND MAINTENANCE INTERVALS

8.2.3.1 GROUNDING CHECK

Every day

Before starting work, carry out a visual check to ensure that the grounding connection is present in the

AquaCoat cabinet and in all relevant components.

8.2.3.2 INSPECTION OF THE SAFETY ELEMENTS

Every day

General visual inspection:

Check for damage or loose contacts:

– Black grounding band in the cabinet door.

– Black grounding bolt on the cabinet door (below),

– Sealing joint for glass window (option).

– Grounding switch on the RH side wall.

– All cables and connections.

Monthly

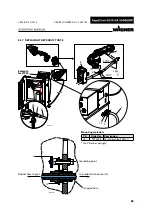

Door switch test:

Open cabinet door (pull hard).

Switch on the control unit.

Switch air on.

Apply "high voltage on" signal to control cables.

– Electrical door switch test:

– The high voltage must remain switched off.

– The control unit displays error E30.

– Pneumatic door switch test:

– The grounding switch must remain closed (below).

Grounding switch test:

Close cabinet door.

Switch on the control unit.

Acoustically ascertain switch movement.

Check that the cabinet door is locked.

Switch off control unit.

Acoustically ascertain switch movement.

8.2.3.3 FURTHER MAINTENANCE INTERVALS

Every day

Check hoses, tubes and couplings: see Chapter

Flush and clean the spray gun in accordance with Chapter

.

Weekly

Check spray guns for damage.

Yearly or as required

In accordance with DGUV regulation 100-500 Chapter 2.29 and Chapter 2.36:

− The liquid ejection devices should be checked by an expert (e.g., WAGNER service technician) for

their safe working conditions as required and at least every 12 months.

− For shut down devices, the examination can be suspended until the next start-up.