21

GM 4600AC

B_00071

B_02262

OPERATING MANUAL

EDITION 05/2011

Part No. DOC394861

5.4

WORKS

5.4.1

START-UP FOR SPRAYING AIRCOAT

1. Start up with material supply set to approx. 8 MPa; 80 bar; 1160 psi operating

pressure.

2. Spray (release trigger safety catch and pull trigger) and check the atomisation.

3. Set the fl uid pressure to the point where a further increase in fl uid pressure would

signifi cantly improve fl uid atomization.

4. Open air pressure controller for the atomizer air and adjust so as to achieve optimal

atomization. (The interrelation between spray pattern and atomizer air is shown in the

fi gure below).

5. Adjust the pressure to get the optimum spraying fi nish. Relation between spray pattern

and shaping air see illustration.

Note:

Repeat point 4 and 5 until the optimum spray pattern is reached (process iterative).

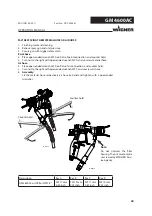

Spray pattern

No atomizing air

too little atomizing air

correct amount of air

5.4.2

ADJUSTING THE SPRAY PATTERN

The spray pattern can be adjusted to suit the object being sprayed using the fan air regula-

tor. The illustration below shows the infl uence of the shaping air regulator on the spraying

pattern.

Other nozzle sizes can be used to obtain larger or smaller spraying patterns.

Shaping air

fully closed

Shaping air

fully open

Note

The paint output volume can be changed by:

•

Changing the material pressure or

•

Fitting another fl at jet nozzle (see chap. 5.4.3 and chap. 9).

Summary of Contents for AirCoat GM 4600AC-H

Page 2: ......

Page 45: ...45 GM 4600AC 45 GM 4600AC OPERATING MANUAL EDITION 05 2011 Part No DOC394861...

Page 47: ......