10

Finish 230 AC Compact

GB

Spraying

5.

Spraying

The AirCoat spray system has two different painting modes. The

AirCoat mode is used for fine finish work with low to medium

viscosity materials (oil, stains, lacquers, etc...). The airless mode is

used for general painting with high viscosity materials (latex).

5.1

Spraying in AirCoat mode

Use the AirCoat mode for low-pressure fine finish work

(recommended pump pressure up to 69 bar (6.9 MPa, 1000 PSI).

1. Make sure that the airless spray hose is free of kinks and clear

of objects with sharp cutting edges.

2. Turn the pressure control knob counterclockwise to its lowest

setting.

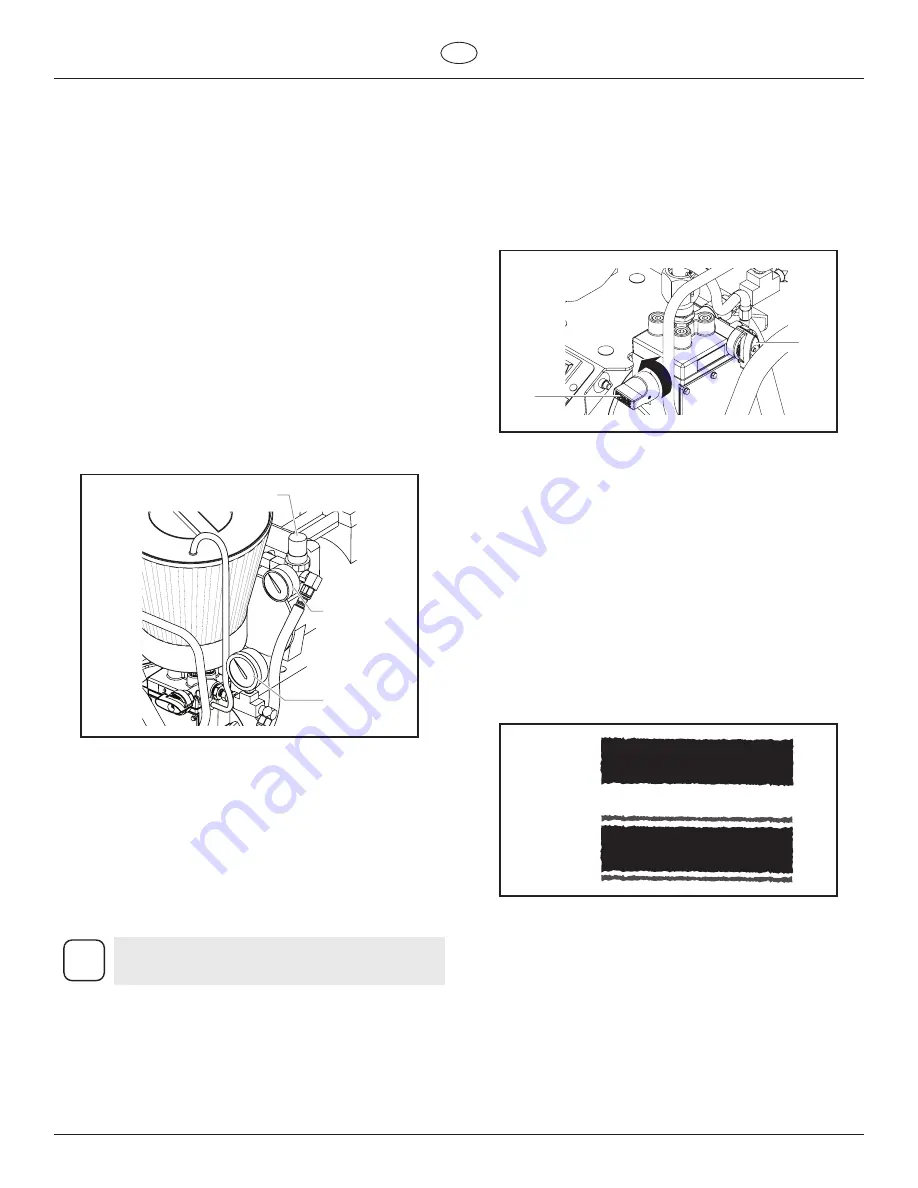

3. Turn the compressor air pressure regulator (b)

counterclockwise to its lowest setting.

4. Move the compressor ON/OFF switch to the ON position.

5. Move the pump ON/OFF switch to the ON position.

6. Turn the PRIME/SPRAY valve to SPRAY.

7. Turn the pressure control knob clockwise until the material

pressure gauge (a) reads 27.5 bar (2.7 MPa, 400 PSI). The paint

hose should stiffen as paint begins to flow through it.

8. Turn the air pressure regulator (b) clockwise until the air

pressure gauge (c) reads 1.3 bar (0.13 MPa, 20 PSI).

(b)

(c)

(a)

9. Unlock the spray gun gun.

10. Trigger the spray gun to bleed air out of the material hose.

11. When material reaches the spray tip, spray a test area to check

the spray pattern.

12. Adjust the spray pattern to the desired size and atomization.

• Use the pressure control knob to control the flow of paint to

the gun.

• Use the air pressure regulator to control the amount of

atomization air available to the gun.

• Use the pattern adjustment knob on the gun to fine tune

the spray pattern.

i

Refer to the spray gun Owner’s Manual for

information on the operation of the gun.

5.2

Spraying in Airless Mode

Use the airless mode for general high-pressure spraying (pump

pressure from 34.4 bar (3.4 MPa, 500 psi) to 193 bar (19.3 MPa, 2800

PSI).

1. Make sure that the airless spray hose is free of kinks and clear

of objects with sharp cutting edges.

2. Turn the pressure control knob (d) counterclockwise to its

lowest setting.

3. Turn the PRIME/SPRAY valve (e) to SPRAY.

(e)

(d)

4. Move the pump ON/OFF switch to the ON position.

5. Make sure the compressor ON/OFF switch is in the OFF

position.

6. Turn the pressure control knob clockwise to its highest

setting. The paint hose should stiffen as paint begins to flow

through it.

7. Unlock the gun by turning the gun lock nut counter-clockwise

(when looking from the back of the gun) three full turns. This

opens the material valve in the gun.

8. Trigger the spray gun to bleed air out of the material hose.

9. When material reaches the spray tip, spray a test area to check

the spray pattern.

10. Use the lowest pressure setting necessary to get a good spray

pattern.

a. If the pressure is set too high, the spray pattern will be too

light.

b. If the pressure is set too low, tailing will appear or the paint

will spatter out in “gobs” rather than in a fine spray.

10a.

10b.