Suction and Discharge Flange

Removal and Installation

NOTE

All suction and discharge flanges are removed the same

way. PT4 is shown.

See

!

WARNING

High temperatures and/or pressures may be

caused during priming or operation. If high

temperatures and/or pressure conditions exist,

do not open any plugs or hoses. Failure to

comply may result in injury or death to

personnel.

NOTE

Both discharge and suction flanges are removed the

same way. The discharge flange is shown.

1.

Support pump securely. (See

"

Figure 2-6: Discharge Flange Removal and

Installation

2.

Remove screws (2) securing discharge flange (1) to

pump (3). Remove discharge flange (1) from pump

(3).

Installation Notes

•

Install discharge flange by reversing the order of

removal.

•

Ensure discharge flange seal is undamaged prior

to installation.

•

Torque discharge flange mounting screws to 7.4

lb-ft (10 N•m).

Spark Plug Inspection

Inspection

!

WARNING

Prolonged contact with lubricating oil may

cause skin rash. Remove saturated clothing

immediately and thoroughly wash skin that

comes in contact with lubricating oil. Failure to

comply may result in injury or death to

personnel.

1.

Support pump securely. (See

"

2.

Remove spark plug.

3.

Using a clean cloth, remove any fuel and dirt from

spark plug.

4.

Using apropriate tool, adjust spark plug gap to

0.024 - 0.028 in. (0.6 - 0.7 mm) gap.

5.

Install spark plug.

6.

Attempt to start pump.

7.

If pump does not start, replace spark plug.

MAINTENANCE

2

5100048604 (12-18)

2-7

Summary of Contents for PT Series

Page 10: ......

Page 12: ......

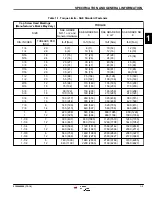

Page 19: ...SPECIFICATION AND GENERAL INFORMATION 1 5100048604 12 18 1 7...

Page 20: ...Page Intentionally Blank SPECIFICATION AND GENERAL INFORMATION 1 1 8 5100048604 12 18...

Page 30: ...Page Intentionally Blank MAINTENANCE 2 2 10 5100048604 12 18...

Page 36: ......

Page 37: ...Notes...