42

13

.

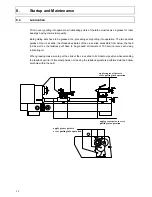

Three jaw-chuck and four jaw-chuck

The three-jaw chuck

serves to clamp circular, triangular and hexagonal workpieces centrically to the spindle axis.

The four-jaw chuck

serves to clamp square workpieces centrically to the spindle axis.

i

Danger of accident

Do not try to clamp larger workpieces. The chucking power is then too low

and the jaws can detach themselves.

Mounting of turning jaws:

The jaws and guides are numbered from 1-3. Open the chuck by means of the chuck key until the

jaws loosen. (order: 3, 2, 1 bzw. 4, 3, 2, 1).

Now, take the inner jaws beginning with the number 1 and put this in the guide number 1. Push the

jaw number 1 in the direction of the centre point of the chuck and at the same time turn the chuck

key (direction "tighten"). When the transverse spiral has taken hold of number 1, number 2 must be

put in the guide provided. The same now happens to number 2 as to number 1. Proceed with

number 3 and number 4 in the same way. Subsequently, examine the position of the jaws.

Mounting of drilling jaws:

If, afterwards, you again want to work with outer jaws, the process repeats itself in the same order

(first jaw 1, then 2, then 3, then 4).

14

.

Collet chuck

Mounting of the tool holder:

When working with the collet chuck, the concentric chuck must be

removed from the workspindle. In order to do this, loosen the three

tightening screws by means of the Allan key SW6 included in the

accessories. Now, the chuck can beremoved from the concentric

flange of the workspindle and the collet chuck can be fixed in the

same way as the lathe chuck.

Collets:

Then press the collet into the union nut and screw it on the collet

chuck.

i

Only those workpieces may be used which accord to the nominal diameter

of the collet chuck.