10

GENERAL FURNACE OPERATION

When you start a

fi

re in the furnace and it reaches operat-

ing temperature, the blower(s) will come on automatically.

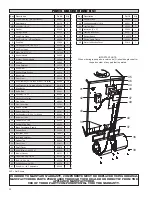

The snap-disc is adjustable from 100°F(A) to 140°F(E),

Each click on the switch is approximately 5°F. It comes

from the factory, set at 120°F, setting C. The rocker switch

on the top of the junction box gives you the option to run

one blower or two. If the switch is ON, both blowers will

come on when the snap-disc reaches the set temperature.

If the switch is OFF, only one blower will operate. When

the furnace temperature drops approximately 20°F below

the snap-disc setting, the blower(s) will shut off.

STARTING A WOOD FIRE

The top down method of

fi

re building is recommended for

this appliance. After making sure that the stove air intake

controls are fully open (completely pull-out towards you),

Place the largest pieces of wood on the bottom, laid in

parallel and close together. Smaller pieces are placed in

a second layer, crossways to the

fi

rst. A third layer of still

smaller pieces is laid crossways to the second, this time

with some spaces between. Then a fourth layer of loose,

small kindling and twisted newspaper sheets tops off the

pile.

Higher ef

fi

ciencies and lower emissions generally result

when burning air dried seasoned hardwoods, as com-

pared to softwoods or to green or freshly cut hardwoods.

DO NOT BURN:

1. Garbage;

2. Lawn clippings or yard waste;

3. Materials containing rubber, including tires;

4. Materials containing plastic;

5. Waste petroleum products, paints or paint thinners, or

asphalt products;

6. Materials containing asbestos;

7. Construction or demolition debris;

8. Railroad ties or pressure-treated wood;

9. Manure or animal remains;

10. Salt water driftwood or other previously salt water sat-

urated materials;

11. Unseasoned wood; or

12. Paper products, cardboard, plywood, or particleboard.

The prohibition against burning these materials does

not prohibit the use of

fi

re starters made from paper,

cardboard, saw dust, wax and similar substances for

the purpose of starting a

fi

re in an affected wood heat-

er.

Burning these materials may result in release of toxic

fumes or render the heater ineffective and cause smoke.

Dead wood lying on the forest

fl

oor should be considered

wet, and requires full seasoning time. Standing dead wood

can usually be considered to be about 2/3 seasoned. Split-

ting and stacking wood before it is stored accelerates dry-

ing time. Storing wood on an elevated surface from the

ground and under a cover or covered area from rain or

snow also accelerates drying time. A good indicator if

wood is ready to burn is to check the piece ends. If there

are cracks radiating in all directions from the center then

the wood should be dry enough to burn. If your wood siz-

zles in the

fi

re, even though the surface is dry, it may not

be fully cured, and should be seasoned longer.

CAUTION: Never use gasoline, gasoline-type lantern fuel,

kerosene, charcoal lighter

fl

uid, or similar liquids to start or

“freshen up” a

fi

re in the furnace. Keep all such liquids well

away from the furnace while it is in use.

CAUTION: To prevent

fl

ame and smoke spillage, the slide

baf

fl

e must be pulled out and the fuel door must be cracked

for ten seconds before being fully opened.

Do not over

fi

re your furnace! After you have become fa-

miliar with its operating, you should know how much wood

to use.

1. Open spin draft cap on ash door.

2. Pull the slide baf

fl

e rod to the front position.

3. Open the fuel load door and light

fi

re using kindling

and several sheets of newspaper, then close the fur-

nace door. The furnace door should remain closed for

5 to 10 minutes in order to establish the

fi

re. If the

fi

re

has established, you are ready to load the furnace.

4. Load the furnace, close the load door and push the

slide Baf

fl

e rod to rear.

5. Close the spin draft cap on ash door, leaving it cracked

about the diameter of a dime.

6. Adjust the spin draft cap on the intake just below the

feed door to allow suf

fi

cient combustion air into the

fi

rebox. This setting may increase or decrease de-

pending on the fuel being used and it’s moisture con-

tent.

7. The blower(s) will being to distribute warm air when

the snap-disc reached set-point.

TESTING AND OPERATING PROCEDURES

FACTORY SETTING

120°F

125°F

130°F

135°F

140°F

100°F

105°F

110°F

115°F