12

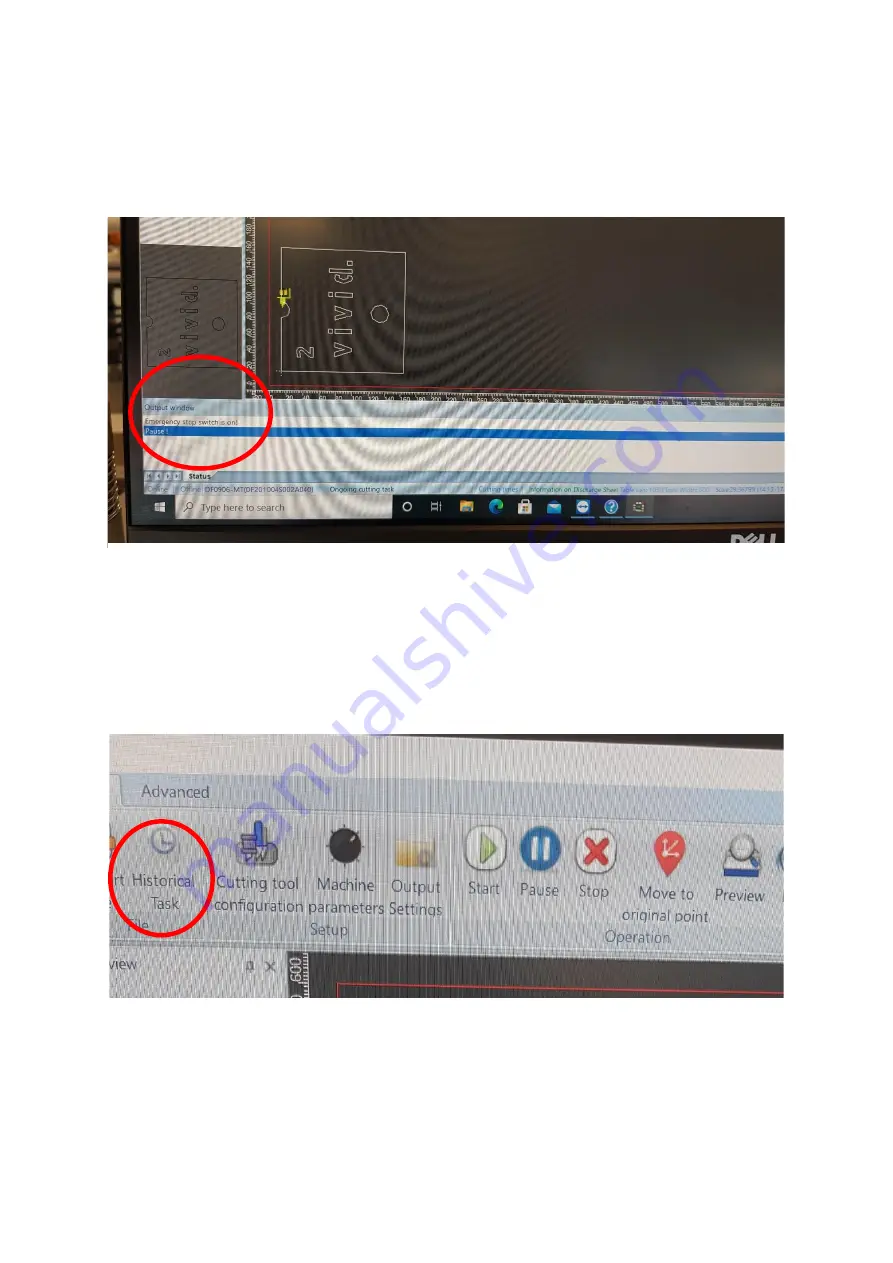

At the bottom of the screen is the Output window [Figure 4.4], this gives the

information of any errors, if the machine is in run/pause mode and or if the

emergency stop buttons are pressed.

The Historic tasks button on the top left of the screen [Figure 4.5], saves

previous cut files that have been used. When restoring a file, right click the file

and press restore. Please note these files cannot be edited and can only be

used in Direct cut mode.

Figure 4.4

Figure 4.5