43

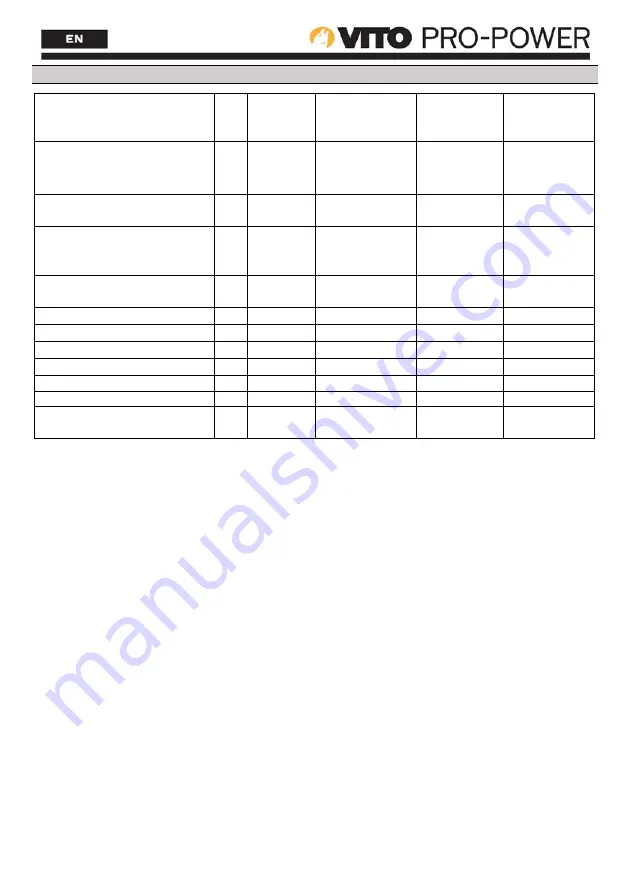

MAINTENANCE SCHEDULE

Action

D

ai

ly

1st month

or 20

hours

Every 3 months

or after 100

hours

Every 6

months or

500 hours

Every year or

after 1000

hours

Clean the motor and check if all

screws and nuts are well

tightened

Check the safety and non-return

valves

Check the condition of pipes,

hoses, couplings, connection

accessories and possible air leaks

Check the condition of the air

receiver tank

Drain out the air tank

Check the air filter

Check

Clean air filter

(1)

Replace the filtering element

Check crankcase oil level

Change oil

Check and replacement of safety

and check valves

(2)

(1) Perform frequent maintenance works when the equipment is used in dusty areas.

(2) These items should be serviced by the service dealer unless you have the appropriate tools and mechanical

knowledge.

Summary of Contents for PRO-POWER VICO25A

Page 1: ...PT EN COMPRESSOR LEO OIL COMPRESSOR ES FR COMPRESOR A ACEITE COMPRESSEUR HUILE VICO25A...

Page 5: ...5 DESCRI O DA FERRAMENTA EL TRICA E CONTE DO DA EMBALAGEM COMPRESSOR LEO 24L 10BAR VICO25A...

Page 19: ...19 DESCRIPCI N DEL EQUIPO Y CONTENIDO DEL EMBALAJE COMPRESOR A ACEITE 24L 10BAR VICO25A...

Page 33: ...33 POWER TOOL DESCRIPTION AND PACKAGING CONTENT 24L 10BAR OIL COMPRESSOR VICO25A...

Page 62: ......

Page 63: ......

Page 64: ...VICO25A_REV00_JAN21...