P16TR

www.vishay.com

Vishay Semiconductors

Rev. 1.2, 18-Apr-18

6

Document Number: 82793

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT

www.vishay.com/doc?91000

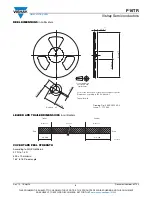

RECOMMENDED METHOD OF STORAGE

Dry box storage is recommended as soon as the aluminum

bag has been opened to prevent moisture absorption. The

following conditions should be observed, if dry boxes are

not available:

• Storage temperature 10 °C to 30 °C

• Storage humidity

≤

60 % RH max.

After more than 72 h under these conditions moisture

content will be too high for reflow soldering.

In case of moisture absorption, the devices will recover to

the former condition by drying under the following condition:

192 h at 40 °C + 5 °C / - 0 °C and < 5 % RH (dry air /

nitrogen) or

96 h at 60 °C + 5 °C and < 5 % RH for all device containers

or

24 h at 125 °C + 5 °C not suitable for reel or tubes.

An EIA JEDEC

®

standard J-STD-020 level 4 label is included

on all dry bags.

EIA JEDEC standard J-STD-020 level 4 label is included

on all dry bags

ESD PRECAUTION

Proper storage and handling procedures should be followed

to prevent ESD damage to the devices especially when they

are removed from the antistatic shielding bag. Electrostatic

sensitive devices warning labels are on the packaging.

VISHAY SEMICONDUCTORS STANDARD

BAR CODE LABELS

The Vishay Semiconductors standard bar code labels are

printed at final packing areas. The labels are on each

packing unit and contain Vishay Semiconductors specific

data.

CAUTION

This bag contains

MOISTURE-SENSITIVE DEVICES

1. Shelf life in sealed bag: 12 months at < 40 °C and < 90 % relative

humidity (RH)

2. After this bag is opened, devices that will be subjected to soldering

reflow or equivalent processing (peak package body temp. 260 °C)

must be

2a. Mounted within 72 hours at factory condition of < 30 °C/60 % RH or

2b. Stored at < 5 % RH

3. Devices require baking befor mounting if:

Humidity Indicator Card is > 10 % when read at 23 °C ± 5 °C or

2a. or 2b. are not met.

4. If baking is required, devices may be baked for:

192 hours at 40 °C + 5 °C/- 0 °C and < 5 % RH (dry air/nitrogen) or

96 hours at 60 °C ± 5 °C and < 5 % RH for all device containers or

24 hours at 125 °C ± 5 °C not suitable for reels or tubes

Bag Seal Date:

(If blank, see barcode label)

Note: Level and body temperature defined by EIA JEDEC Standard J-STD-020

4

LEVEL

22522

22645