12

Ø c

ee

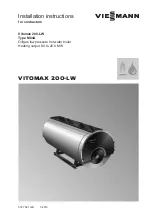

Fig. 6

c Max. flame head diameter

e Minimum flame head length (table 4)

Separate burner instructions,

connection and wiring schemes

as well as operating and service

instructions.

1.

For the burner connection, secure the

burner plate to the boiler flange with

screws.

Note

If the burner plate was not pre-drilled

at the factory, drill the burner fixing

holes into the burner plate and cut out

the flame head aperture.

2.

Secure the burner to the burner plate

with screws.

Note

For different dimensions, adjust the

cut-out in the thermal insulation

according to the flame head diame-

ter.

3.

After mounting the burner, seal the

annular gap between the flame head

and the thermal insulation block with

heat-resistant insulation material.

Note

Thermal insulation blocks and loose

thermal insulation are supplied either

inside the reversing chambers of the

boiler doors or inside the flame tube.

4.

Close the boiler doors and cleaning

aperture at the back of the boiler.

Note

Check for gas tightness.

Mounting the burner

5727 521 GB

Summary of Contents for VITOMAX 200-LW

Page 15: ...15 5727 521 GB...