Combustion equipment for LPG (propane, butane and their mixtures)

may only be installed in rooms whose floor is more than 1 m below

ground level at every point, subject to the following conditions:

■ The combustion equipment is equipped with a flame monitoring

device.

■ It is ensured that LPG cannot escape from the fuel lines inside the

installation room in dangerous quantities or will be extracted safely

via a mechanical ventilation system, even if the combustion equip-

ment has been switched off.

Combustion equipment must be installed at a sufficient distance from

combustible materials and fitted furniture, or be shielded from them, to

ensure the temperature on such materials/furniture does not exceed

85 °C when the combustion equipment is delivering the rated heating

output. Alternatively, maintain a distance of at least 40 cm.

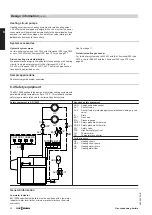

Safety equipment for the installation room for Vitocrossal 300, type CM3

Viessmann boilers are tested and approved in accordance with all

safety regulations and are therefore fail-safe. Unpredictable, external

factors may, in the rarest of cases, lead to the potentially harmful

escape of carbon monoxide (CO). For this case, we recommend using

a CO limiter. This can be ordered as a separate accessory (part no.

7499 330).

8.2 System design

Performance limits in regulations

In many regulations, the conditions to be met are subject to the rated

boiler heating output. For this, the output at TF/TR 80/60 °C is deci-

sive.

However, the output levels given in this technical guide relate to the

specification at TF/TR 50/30 °C (type CM2, CM3, CT3U and CR3B)

and 40/30 °C (type CT3B), which is now commonly applied to con-

densing boilers.

The rated heating outputs at both TF/TR can be found in the table on

page 21.

Flow temperatures

To keep distribution losses to a minimum, we recommend that the:

■ Heat distribution system and the

■ DHW heating is designed for a max. of 70 °C (flow temperature).

On boilers supplied with a boiler control unit, the max. boiler water

temperature is limited to 75 °C. The flow temperature may be

increased by adjusting the temperature controller.

Pump controlled pressure maintaining systems

In heating systems with automatic pressure maintaining systems, and

in particular pump controlled systems with integral deaeration, we rec-

ommend the installation of a diaphragm expansion vessel for individual

boiler protection. This reduces the frequency and level of pressure

fluctuations. This contributes considerably to improved operational

reliability and longer service life of the system components. Failure to

observe these recommendations may result in damage to the boiler or

to other system components.

Boiler output (kW)

Diaphragm expansion vessel

Capacity in litres

up to 300

50

up to 500

80

up to 1000

140

up to 2000

300

up to 5000

800

up to 10,000

1600

Furthermore ensure that only pump controlled pressure maintaining

systems that are sealed against corrosion and protected against oxy-

gen ingress into the heating water are used. Otherwise damage to the

system through oxygen corrosion can result. Pump controlled pres-

sure maintaining systems with atmospheric deaeration through cycli-

cal pressure release create a central post-ventilation of the heating

system. However, this does not represent oxygen removal in the sense

of corrosion protection as described in VDI 2035 Sheet 2.

Safety temperatures

Viessmann boilers correspond to EN 303 and DIN 4702 and all are

type-tested. They are suitable for installation in sealed heating sys-

tems to EN 12828. Permiss. flow temperatures (= safety tempera-

tures): up to 110 °C. Max. achievable flow temperature: approx. 15 K

below the safety temperature.

High limit safety cut-out of the boiler control unit

Delivered condition

Adjustable to

110 °C

100 °C

For the Vitocrossal, the high limit safety cut-out must be changed over

to 100 °C.

Note

Once changed, the hydraulic-mechanical high limit safety cut-out can-

not be reset to the higher value.

Design information

(cont.)

20

VIESMANN

Gas condensing boilers

8

5822 449 GB