Connections

Connections

8

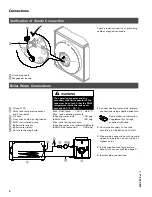

Verification of Anode Connection

Check proper connection of grounding

cable at magnesium anode.

Grounding cable

Magnesium anode

Boiler Water Connections

Vitocell 100

DHW tank temperature sensor

and/or aquastat

Air vent

Flow check valve, spring-loaded

DHW recirculation pump

Boiler water supply

Boiler water return

Hot water heating boiler

Max. supply temp.

230

º

F / 110

º

C

. . . .

Max. DHW temp.

150

º

F / 65.6

º

C

. . . . . .

Max. tank operating pressure

H

heating water side

150 psig

. . . . . . . . . . . . . .

H

DHW side

150 psig

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Max. tank testing pressure

H

heating water side (primary)480 psig

H

DHW side (secondary)

300 psig

. . . . . . .

1.

Connect heating water side (primary)

connections using supplied adaptors.

See Installation Instruction

Supplement for fittings

supplied with tank.

2.

Control heat supply to the tank

according to illustration on the left.

3.

Pipe supply connections with upward

slopes and install an air vent valve at

highest point.

4.

Install supplied tank temperature

sensor into sensor well (see page 7).

5.

Insulate pipe connections.

5167

514

v1.1

5167

514

v1.1

The operating aquastat and any

secondary high limit aquastat of the

tank must be set such that the DHW

temperature inside the tank never

exceeds 203 °F / 95 °C.

WARNING