7

Checking the gas type

1.

Determine the gas type and Wobbe

index (Wo) from your gas supply util-

ity.

■ With the

natural gas E setting

, the

boilers can be operated in the

Wobbe index range 12.0 to

16.1 kWh/m

3

(43.2 to 58.0 MJ/m

3

).

■ With the

natural gas LL setting

,

the boilers can be operated in the

Wobbe index range 10.0 to

13.1 kWh/m

3

(36.0 to 47.2 MJ/m

3

)

(not in

a

and

c

).

2.

In the delivered condition, the burner

is set up for natural gas E. If required,

convert the burner to the other gas

type in accordance with details provi-

ded by your gas supply utility (see

page 7).

3.

Record the gas type in the report (on

page 45).

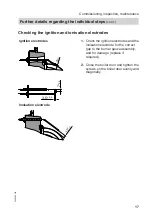

Conversion to natural gas LL

(not in

a

and

c

)

C

B

A

0

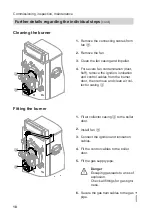

1.

Close the gas shut-off valve.

0

2.

Switch OFF the control unit ON/OFF

switch.

0

3.

Switch OFF the main isolator (out-

side the installation room) or the

power supply and prevent unauthor-

ised reconnection.

0

4.

Release the cable fixings on the gas

pipe.

0

5.

Release compression fittings

A

and

C

remove the gas pipe.

0

6.

Unscrew gas restrictor

B

.

0

7.

Take gas restrictor

B

for natural

gas LL from the pack supplied and

screw on (for diameter see table on

page 46).

Commissioning, inspection, maintenance

Further details regarding the individual steps

(cont.)

5692 488 GB