32

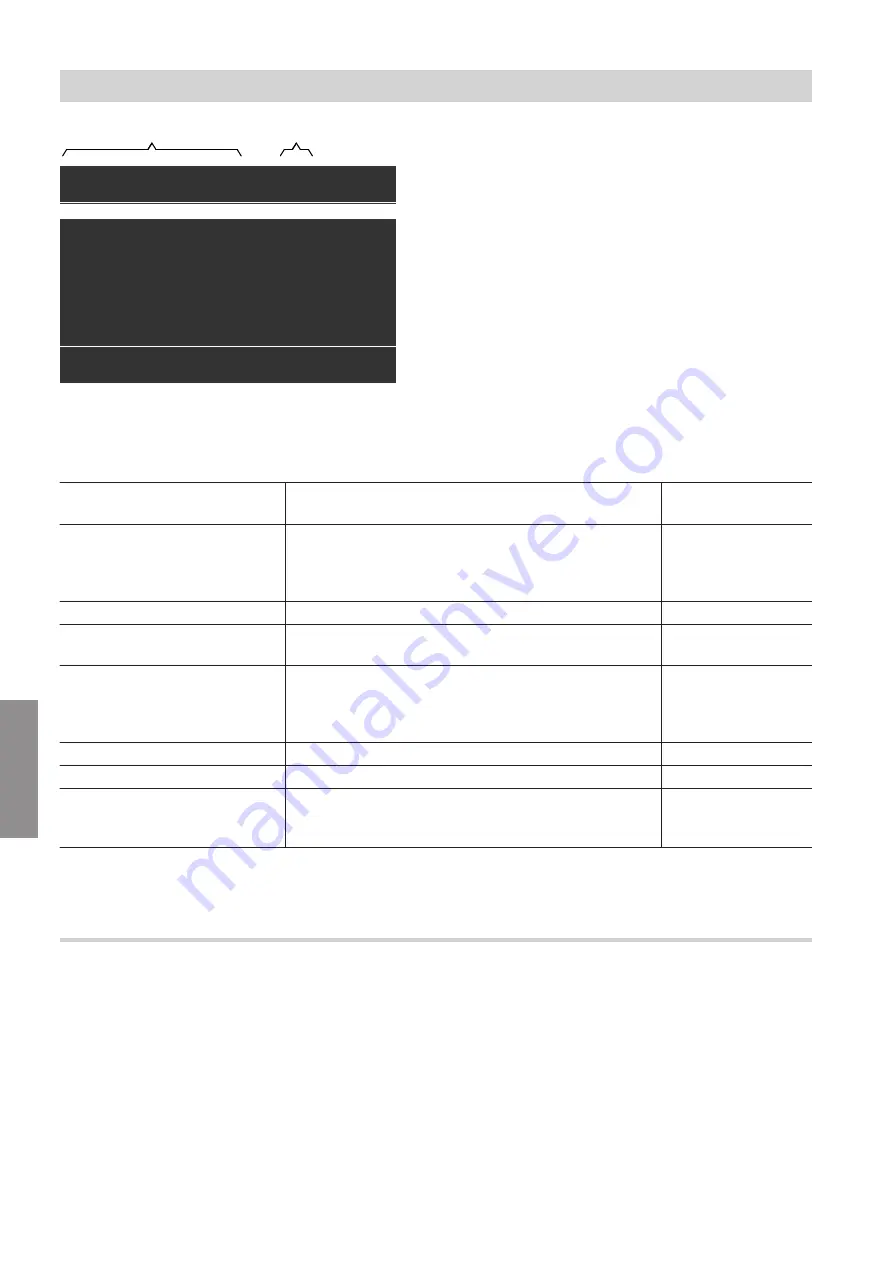

Timer

Select with

(

A

B

Ü

Min. runtime heat pump

Opt. runtime heat pump

106

6118

30

Start-up time heat pump

Heat pump blocking time

426

Fig. 10

A

Active events

B

Remaining time in s

Active events

Meaning

Factory-set time de-

faults

"Start-up time heat pump"

Advance runtime for primary pump and secondary

pump:

Of no significance, as primary pump and secondary

pump are not connected.

60 or 120 s

"Min. runtime heat pump"

Minimum runtime for increasing heat pump efficiency

120 or 180 s

"Opt. runtime heat pump"

Time during which the COP has an almost linear pat-

tern.

10 or 20 min

"Pump run-on time heat

pump"

Secondary pump run-on time, after which heating op-

eration with the heat pump ends:

Of no significance, as secondary pump is not connec-

ted.

—

"Heat pump blocking time"

Pause to reduce compressor wear

180 or 600 s

"Refrigerant circuit functions"

Max. time for suction gas pressure control

10 min

"HP protection functions"

Max. time, during which the minimum temperature dif-

ferential between condenser and evaporator does not

have to be reached.

10 min

Note

If no process is active, the display shows

"No timer

active"

.

Integral

Excessively frequent starting and stopping reduces the

service life of the compressor. For this reason, the

compressor only starts when the min. return tempera-

ture is consistently undershot. The heat pump control

unit takes into account the extent and duration of the

undershooting via the output integral.

The compressor only starts if the output integral has

exceeded the

"Start threshold 730E"

.

The

"Integral"

display indicates the current extent of

the output integral.

1. Service menu:

Press

OK

+

å

simultaneously and hold for

approx. 4 s.

2. "Diagnosis"

3. "System"

4. "Integral"

Diagnosis

System

(cont.)

5800 917 GB

Diagnosis