VD520 Series Inverter User Manual Parameter Description

- 97 -

Chapter 6 Parameter Description

F0 Basic Function

F0-00

Motor Control Mode

Led unit’s digit: motor 1

0: V/F control

1: SVC

Led ten’s digit: motor 2

0: V/F control

1: SVC

0x00

◎

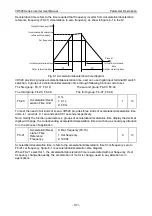

0: V/F control mode:

Suitable for load demand is not high, or a frequency inverter drive multi-motors application, such as

fan and pump load.

1: SVC

Refers to the open loop vector control, suitable for the usual higher performance control occasions,

one frequency inverter can only drive a motor. Such as machine tools, centrifuge, wire drawing

machine, injection machine and the load.

Tip: when select the vector control mode must done motor parameter identification process. Only

accurate motor parameter can give a full pay to the superiority of the vector control mode. By

adjusting the speed regulator parameter F3 group function code (motor 2 is A3 group), can obtain

better performance.

F0-01

Running Command

Source

0: Control panel command source (L/R OFF)

1: Terminal command source (L/R ON)

2: communication command source (L/R

flashes)

0

○

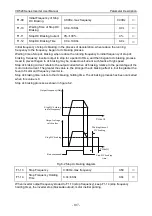

Select inverter run command source:

Inverter run command include: start, stop, forward run, reverse run, jog, etc.

0: Control panel command source (L/R OFF)

Key” RUN, JOG/REV, STOP/RESET” on control panel to realize command control.

1: Terminal command source (L/R ON)

Through multi-function input terminal to realize command control.

2: Communication command source (L/R flashes)

Operation command as setup via HOST PC via communication mode, when select this option, default

is Modbus communication (standard), can optional communication card (Profibus-DP card or

CANopen card, etc.).

And the communication related

function parameters, see “Fd group communication parameters”

instructions, and reference the corresponding communication card added, supplemented by the

communication card with communication card, the appendix of this manual contains brief description

of communication card.