Air Fittings Leak

1. Loose fitting connections

2. Air line tubing not published

all the way or cut squarely

1. Check connections with soap

& water solution. Reapply

sealant to fitting, reassemble.

Do not over-tighten.

(Make sure system pressure is

released before making repairs).

2. Remove air line, cut off one

inch, and reinstall.

Gauge leaks

1. Gauge connection loose

2. Air line not pushed all the way

in or cut squarely.

1. Remove air line from back of

gauge, cut off one inch, and reinstall.

2. Tighten compression fitting collar.

Compressor hooked up to

system will not run.

1. No power or ON/OFF switch is

in the OFF position.

2. Compressor hooked up to

system will not run.

1. Make sure power wire is

properly connected, and the ON/

OFF switch on Dash Panel

Gauge is in the ON position.

2. Check for the proper fuse

amperage. Replace fuse if needed.

Compressor hooked up to

system runs continuously.

1. Defective pressure switch.

2. If your air tank set up has a

safety valve, check for

defective safety valve.

1. Replace pressure switch.

2. Replace safety valve.

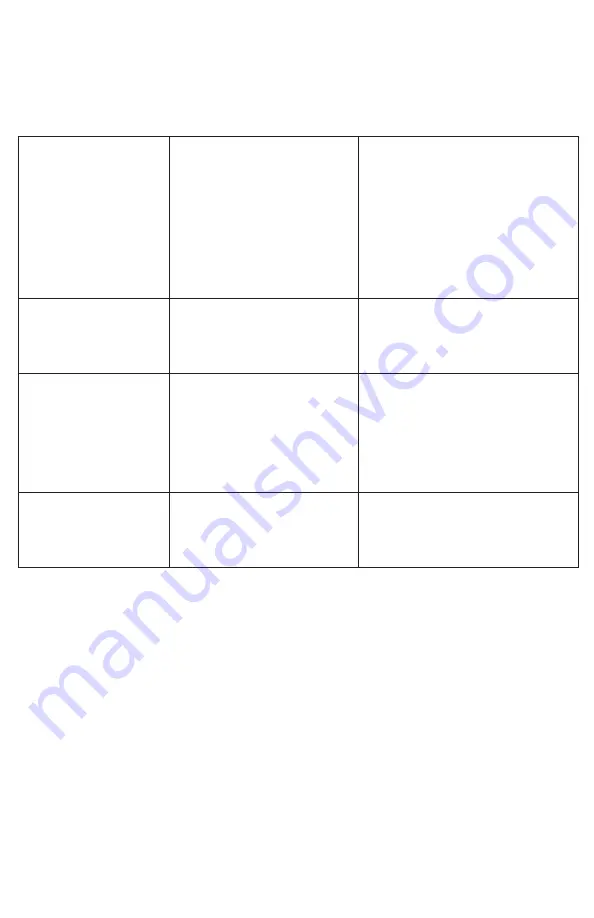

TROUBLESHOOTING GUIDE:

PROBLEM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION