Fig. 13: Shaft fork arm suspension

To ensure a reliable check, first dismantle

Chapter 6.6 “Replacing the fork arms”

Chapter 6.5 “Cleaning the fork carrier and fork arms”

n

Check the welds of the fork sockets for cracks, deformation, and wear. If defective,

immediately ban any further use of the shaft fork arms. Commissioning must only be

carried out after a successful repair.

n

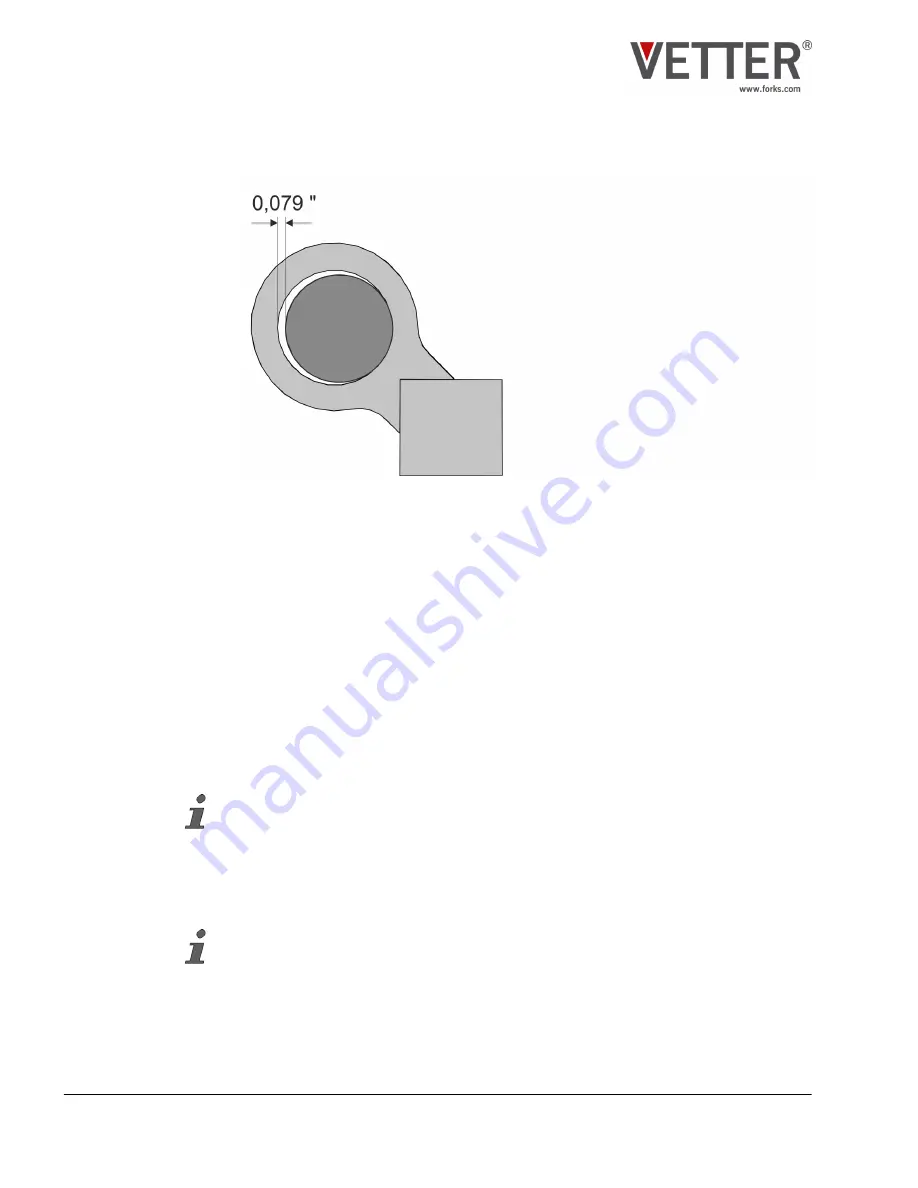

Check the sockets of the fork arms for deformation and wear. To do so, measure the

inner dimension of the fork socket and the diameter of the shaft using a caliper

gage. If the differences are greater than 0.079 mm inches (2 mm) (Fig. 13), the per-

missible value has been exceeded. In those cases, replace the fork arms in pairs

immediately.

6.4.3

Crack test for fork arms

Have crack tests performed in the area of the fork bend and fork hook welds by a

trained service specialist. If there are any signs of cracks, immediately ban any further

use of the fork arms.

6.4.4

Deformation of the fork arms

If the geometry of the unloaded fork no longer corresponds to the delivery state, there

is deformation present. The straightening of fork arms must only be performed by the

manufacturer or by a company authorized by the manufacturer.

Maintenance

Checking the fork arms > Deformation of the fork arms

Fork carrier with fork arms

36

Summary of Contents for ManuTel

Page 2: ...Fork carrier with fork arms 2 ...

Page 52: ......