16

■

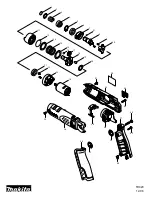

Installation

2)

Mounting

the

spring

of

the

tip

arm

‐

When

purchased,

the

spring

of

the

tip

arm

is

not

mounted

on

the

one

side.

As

shown

in

the

figure

on

the

right,

insert

the

spring

shaft

into

the

hole

and

tighten

with

a

lock

nut.

At

this

time,

mounting

is

easier

if

you

lift

the

tip

arm

above

while

working.

‐

There

are

two

mount

holes,

but

only

use

the

mount

hole

on

the

intermediate

bracket

side.

*Caution:

Hang

the

spring

hook

correctly,

(refer

to

the

right

fig.)

*Engage

the

hook

into

the

groove

of

the

plastic

part.

*If

used

for

a

long

time

with

the

spring

mounted

incorrectly,

it

may

significantly

shorten

the

durability

life

of

the

spring.

*Caution:

Tighten

firmly

to

reach

the

nylon

lock

part,

to

prevent

the

nut

from

loosening.

*Caution:

Do

not

place

your

fingers

or

hands

close

to

the

rotating

parts

and

moving

parts.

3)

Setting

the

height

‐

The

working

height

position

is

fixed

using

M6

cap

screws

on

the

collars.

‐

Tighten

the

M6

hex

socket

head

bolts

on

the

collars

firmly.

If

not

tightened

firmly

enough,

the

main

body

may

fall

rapidly,

causing

great

danger.

*Caution:

When

loosening

the

collar

on

the

base

bracket

bottom

side,

support

the

arm

with

one

hand

while

working

so

that

the

arm

does

not

fall

rapidly.

*Caution:

The

recommended

tightening

torque

of

the

M6

hex

socket

head

bolt

is

1.5

N

m.

If

it

is

tightened

too

tightly,

the

brass

part

on

the

tip

of

the

fix

screw

may

deform,

and

may

cause

the

pillar

to

deform.

If

the

pillar

is

deformed,

the

height

of

the

arm

may

become

unadjustable.

①

Lift

the

arm

②

Insert

spring

shaft

M6

Cap

Screws

Summary of Contents for HFB-300-1

Page 9: ...9 MEMO ...

Page 19: ...19 MEMO ...