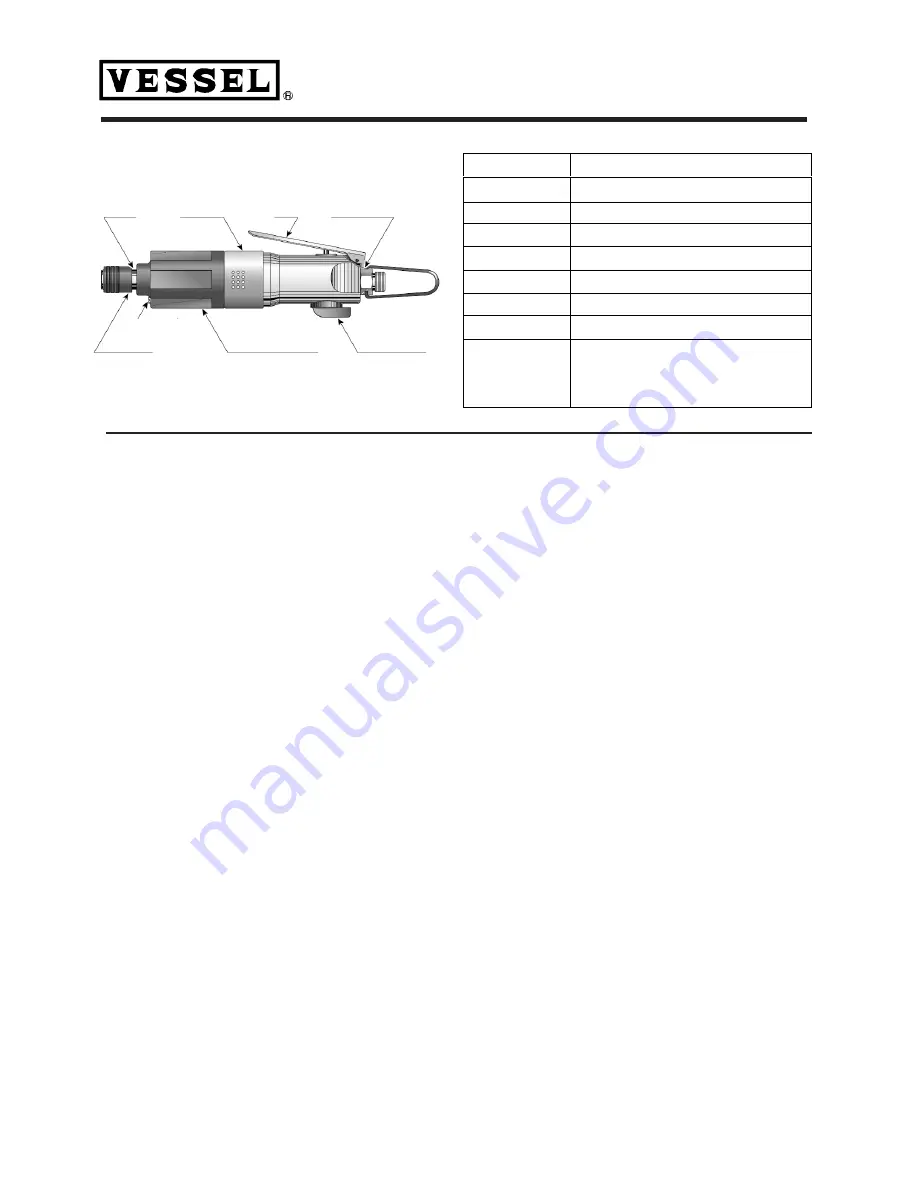

GT-S4.5XD

AIR SCREWDRIVER

INSTRUCTION MANUAL

Model

GT – S4.5XD

Capacity

4.0 - 5.0mm

Free Speed

14,500r.p.m.

Overall Length

188mm

Weight

585g

Air Consumption

0.2m

3

/min

Inner Hose Diam.

6.35mm

Air Pressure

0.6MPa

Accessories

Both End Bit (A14 +2x65G) 1PC

VESSEL Air Plug (BPB-2F) 1PC

ISO VG-10 lubrication oil (Clear)

15cc

ISO VG-32 lubrication oil (Light Green) 15cc

■

LUBRICATION

1. Lubrication is indispensable to air tools.

It is necessary to install a lubricator for automatic oil

feed, but if it is not available, manual lubrication

twice a day is recommended for longer product life

and efficient function of its mechanism. The package

contains two different kinds of lubrication oils.

2. To lubricate the motor part, remove the air hose

from Air Inlet Bushing. Then apply appropriate

amount of lubrication oil for rotating mechanism

(VG-10, Clear) into Air Inlet and conduct several

seconds’ idling.

3. To lubricate the impact-driving parts, remove

Lubricant Port Screw and apply one to two drops

of lubrication oil to impact mechanism (VG-32, Light

Green) once a week.

To replace spent lubricant, remove Lubricant Port

Screw and dispose of the old lubricant. Then refill

the hammer housing with 10cc volume of new

lubrication oil for impact driving mechanism

(VG-32, Light Green). Excessive lubrication lowers

the working torque.

■

AIR SUPPLY

1. Air tools can be adversely affected by moisture.

As air supplied from air compressors contains a lot

of moisture and dust, it is advisable to install filtering

equipment and a lubricator in the pipeline to remove

such undesirable elements. Also, accumulated

water in the air tank needs to be drained every day.

2. Before using a new air hose or air pipe, connect it to

the air compressor first to run a flow into it so that

the inside of it will be cleaned.

3. Keep the inside of air hoses and air pipes clean.

With dust and water accumulated within an air hose

or pipe, the inner diameter of them becomes smaller

and it causes a drop in the working air pressure.

It can also cause the air tools to break down if such

objects get into them.

4. If the air hose is detached from the tool, keep the

end of the hose from falling onto the floor as dust

or other objects may come into the air hose.

5. The input air pressure needs to be maintained

within the 0.55MPa to 0.60MPa range by installing

a regulator at the tool end. Excessive air pressure

shortens the lifetime of impact-driving parts and

insufficient air pressure lowers the working torque

and causes its performance to be impaired.

6. Please conduct “idling” for a few seconds after

lubrication, as the lubricant would be flushed out

with exhaust air.

7. VESSEL Quick-Change Couplings are recommended

for more convenience.

■

OPERATION

1. Do not tamper with the rotational parts as they are

adjusted with high precision. In case of malfunction,

please contact us for customer service.

2. Switch Reverse Lever to L (for counter-clockwise

revolution) or R (for clockwise revolution) to change

the rotational direction.

3. Set the tool to the screw and press Throttle Lever

to start.

4.

Release Throttle Lever to stop the revolution after

completing the fastening job. Unnecessary driving

will damage both the screw / bolt and the impact-

driving mechanism.

5.

Do not use the Throttle Lever to hang the unit.

The use of proper hanging equipment is required.

6.

Avoid idling the unit with no load, except for the

after-lubrication flush (Refer to the 6th note of

AIR SUPPLY).

■

SPECIFICATIONS

Cover with Air Outlet

Anvil (Rotatable) Throttle Lever Air Inlet Bushing

Lubricant

port screw

Bit Sleeve Hammer Housing Reverse Lever