3

2.4.4 Connecting Battery Cable

The power system can be accessed in one group of batteries controlled by a battery MCB.

The battery MCB is located on the front panel of the power system and the battery

connection terminal is at the rear right side of the subrack. During connection, connect the

negative battery cable to the battery terminal '-' and then connect the positive battery

cable to the battery terminal '+'. Terminal connection method:

As shown in Figure 2-10,

use a flat-blade screwdriver, gently pull out the insulation film to prevent short circuit,

loosen the screw, insert the corresponding cable end into the corresponding positive and

negative terminals, and then tighten both screws. After that cover the terminal screw with

the insulation film to avoid accidental short circuit.

Screwdriver

Battery input

Screwdriver

Battery input

Battery input terminal

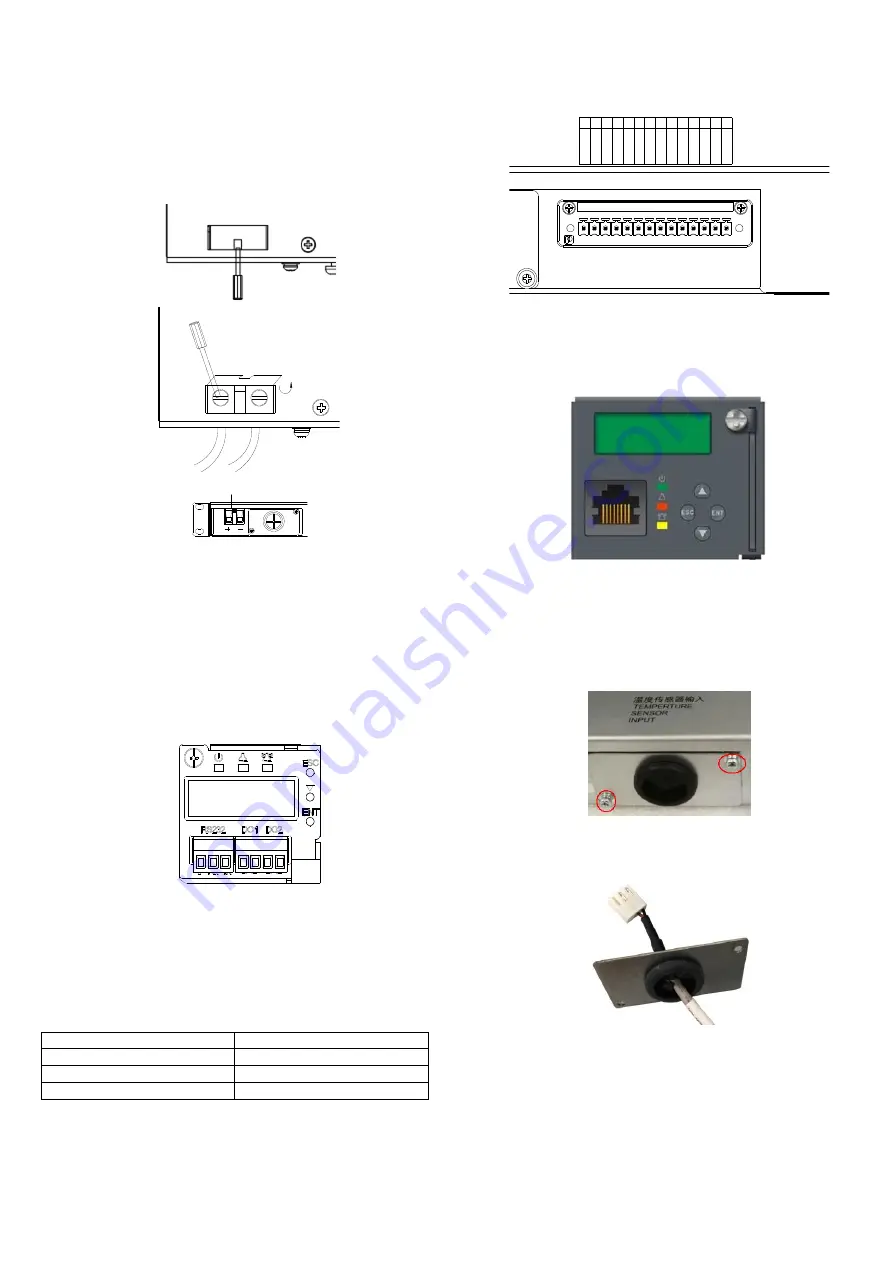

Figure 2-10 Illutration of battery connection terminal

2.4.5 Connecting Communication Cable

Connecting M225S dry contact output port

The controller is configured with two pairs of alarm dry contact output (DO1 ~ DO2) as

standard configuration and four expanded outputs (DO3 ~ DO6) as optional. The dry

contact that generating corresponding alarm is normally closed, users can connect

according to actual needs. When wiring, connect the multi-core communication cable with

the pipe terminal to the corresponding dry contact according to the dry contact silkprint

on the controller, and then insert the terminal into the controller front panel. The position

of communication terminal and port definition are shown in Figure 2-11 (Users need to

prepare signal cable themselves).

Figure 2-11 Illutration of controller front panel

Connecting RS232 port of M225S controller

The RS232 port is used for communication with the host. The correlation of the RS232 and

DB9 port on the host is shown in Table 2-2. When wiring, connect the multi-core

communication cable with the pipe terminal to the corresponding terminal according to

the RS232 port silkprint on the controller, and then insert the terminal into the controller

front panel, as shown in Figure 2-11 (Users need to prepare signal cable themselves).

Table 2-2 Correlation of ports

RS232 port

DB9 port

1 (Tx)

2

2 (Rx)

3

3 (GND)

5

Connecting M831A dry contact output port

The controller is configured with four pairs of alarm dry contact output (DO1 ~ DO4) as

standard configuration and two routes of DI input and one route of RS485 output. The dry

contact that generating corresponding alarm is normally closed, users can connect

according to actual needs. The two routes of DI input only need to input DI dry contact and

no need to input external power. When wiring, connect the multi-core communication

cable with the pipe terminal to the corresponding dry contact according to the dry contact

silkprint on the controller, and then insert the terminal into the controller front panel. The

position of communication terminal and port definition are shown in Figure 2-12 (Users

need to prepare signal cable themselves).

DO1-COM

1 2 3 4 5 6 7

8 9 10 11 12 13 14

DO1-NC/NO

DO2-COM

DO2-NC/NO

DO3-COM

DO3-NC/NO

DO4-COM

DO4-NC/NO

DI1-1

DI1-2

DI2-1

DI2-2

RS485A

RS485B

Figure 2-12 Illutration of NetSure 2100 A31-S3 rear signal output

Connecting Ethernet port of M831A controller

The front panel of M831A is configured with an Ethernet port. When wiring, just insert the

network cable into the Ethernet port, as shown in Figure 2-13 (Users need to prepare

network cable themselves).

Figure 2-13 Illutration of M831A controller front panel

2.4.6 Connecting Temperature Compensation Cable

For NetSure 2100 A31-S2 configuration, the corresponding controller is M225S, and a

battery temperature compensation cable (Temp. cable for short) is configured. Take out

the Temp. cable from the accessory at the site and connect the cable as follows.

1. Loosen the two screws fixing the panel at the rear of the subrack, and use a knife to cut

along the cross center of the rubber ring, as shown in Figure 2-14.

Figure 2-14 Lossening the fixing screw

2. Lead the white terminal of Temp. cable through the rubber ring, as shown in

Figure 2-15.

Figure 2-15 Leading the cable through rubber ring

3. Pull out the terminal labeled ‘Temp’ fromt the subrack power supply, as shown in

Figure 2-16.