11 PREVENTIVE MAINTENANCE WORKSHEET

Source: DPN002955, Rev. 2

Inspection Date

Job Name

Indoor Unit Model #

Indoor Unit Serial Number #

Room Temperature/Humidity

°

%

Cooling Module #

Good maintenance practices are essential to minimizing operation cost and maximizing product life. Read and follow all

applicable maintenance checks listed below. At a minimum these checks should be performed semi-annually. However,

maintenance intervals may need to be more frequent based on site-specific conditions. Review the unit user manual for

further information on unit operation. Vertiv recommends the use of trained and authorized service personnel, extended

service contracts, and factory certified replacement parts. Contact your local Vertiv Representative for more details.

Cabinet and Coil

1.

Wipe inlet and out grills clean.

2.

Wipe fans and fan inlets clean.

3.

Verify coil is clean.

Electrical Panel

1.

Check fuses.

2.

Check/re-torque wire connections.

Controls

1.

Check/verify control operation (sequence).

2.

Check/test changeover devices (if equipped).

3.

Check/test water detection devices (if equipped).

Pump

1.

Check for pump motor bearing noise.

2.

Verify pump suction pressure is above 10 ps.

Suction:

3.

Pump amp draw

#1

L1

L2

L3

#2

L1

L2

L3

4. Verify pump changeover (if multiple pumps).

11 Preventive Maintenance Worksheet

49

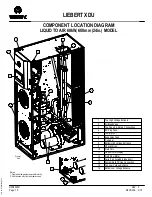

Summary of Contents for Liebert XDU 060

Page 1: ...Liebert XDU Liquid to Air Heat Exchanger for Chip Cooling Installer User Guide 600 mm Wide ...

Page 10: ...Vertiv XDU Liquid to Air Heat Exchanger for Chip Cooling 6 This page intentionally left blank ...

Page 38: ...Vertiv XDU Liquid to Air Heat Exchanger for Chip Cooling 34 ...

Page 74: ...Vertiv XDU Liquid to Air Heat Exchanger for Chip Cooling ...