9. Once each part has the left end processed, place the offset

gauge in the hole in the right-angle fence and adjust the

gauge so the cursor registers against the inside surface of

the outermost spring stop on the front face of the Domino.

10. Lock this setting, and then remove the offset gauge from the

right-angle fence and set it aside.

Note:

While there are a number of features on the face of the

Domino that can be used for reference alignment, make it a habit

to consistently use the same reference point. In our example, our

reference point is the inside surface of the outermost spring stop

on the front face of the Domino.

11. Reposition the right-angle fence on the right side of the

Domino and place the offset gauge in the hole in the fence.

12. Slide the fence/gauge assembly until the cursor is aligned

with the inside surface of the outermost spring stop.

13. Ensure the right-angle fence is tight against the fixed fence.

Lock it in place using the wing knobs.

14. Remove the offset gauge.

15. Make a test cut with a scrap piece of the frame material to

ensure the set-up is correct and the desired mating right joint

alignment is achieved.

16. If all is correct, proceed to cut the right mortises in all the

parts. (If not, adjust as required.)

Cutting Mortises in Butt Joints

Butt-jointed frames require a bit more care than mitered joints as

far as marking the parts and being vigilant regarding “left” and

“right” ends of the part.

Note:

As with all joinery cut by machine, it is good practice to

have a number of extra parts to use for testing the set-up. This is

particularly important when configuring the joinery table for the

second half of the joint.

1. Cut all the parts of your project/frame to length.

2. Lay out the parts to form the frame and mark all the joint

locations to indicate which side is up, as well as which edge

is out. In our example, we used a double line parallel to and

across the parts that will receive the mortises. On either

side of the mortise marks, we scribed a perpendicular line

extending to the outer edge of each part to indicate the outer

edge of the frame.

3. On at least one of the joints, also clearly mark where the

center of the mortise should be on that surface. In our

example, we used a capital letter R. This reference mark will

be used for the initial set-up of the joinery table.

4. Using the part specifically marked for set-up, align the

reference mark with the centerline mark on the face of

the Domino.

5. Ensure the part is tight against the fixed fence and clamp the

part in place with at least one hold-down.

6. Slide the right-angle fence against the end of the part that is

marked as the outside of the frame, ensuring it is also tight

against the fixed fence. Lock the right-angle fence in place

using the wing knobs.

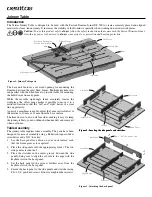

Figure 16: Cutting the mating Domino mortises.

Figure 14: Setting the offset gauge.

Spring Stop

Offset Gauge

Cursor

Right-Angle

Fence

Figure 15: Reversing the right-angle fence and setting the mortise

distance with the offset gauge.

Outermost

Spring Stop

Cursor

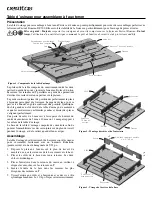

Figure 17: Butt-joint frame. Note the corner markings designate

which surface gets a mortise (two lines) and which surface is the

outside of the frame (one line).

Reference Mark

Mortise Mark

Outside Mark

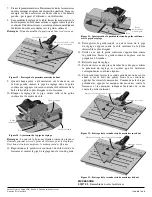

Figure 18: Cutting the first side-grain mortise.

Reference Mark

Outside mark against

the right-angle fence

4