SERVICE

Service - 20

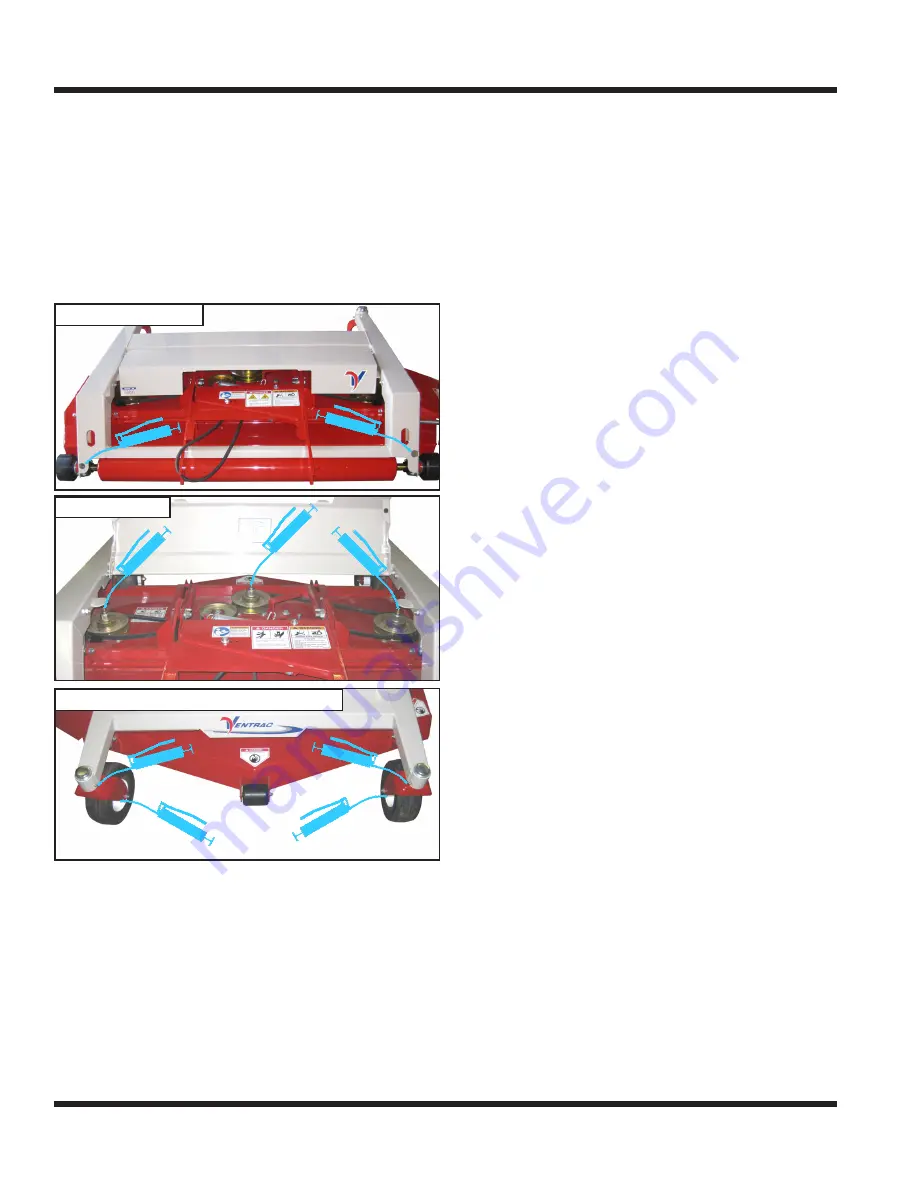

Lubrication

Lubrication is required at the following locations. Use

a lithium complex NLGI #2 type grease. Refer to the

maintenance schedule for service intervals.

When greasing the rear roller bearings, if the car-

rier frame is not equipped with access holes, flip the

mower deck up into the service position (See Deck

Flip-Up Procedure section) and raise the mower deck

to the highest cutting height setting to access the

grease fittings.

Mower Spindles

Rear Roller Bearings

Carrier Wheel Pivot & Wheel Axle Bearing

Storage

Preparing the Mower for Storage

1. Clean the mower deck and frame.

2. Inspect for loose or missing hardware, damaged

components, or signs of wear. Repair or replace

any damaged or worn components

3. Inspect belts, spindles, and blades. Repair or

replace any damaged or worn components

4. Apply grease to all grease points.

5.

Wipe off all excess grease or oil.

Removing the Mower from Storage

1. Clean the mower deck to remove any accumu-

lated dust or debris.

2. Inspect the mower deck as instructed in the daily

inspection section of this manual.

3. Test the mower deck to ensure all components

are working properly.