8

VUT/VUE 270 V5(B) EC

www.ventilation-system.com

DESIGN AND OPERATING PRINCIPLE

The unit has the following operating logic: warm stale extract air from the room flows into the unit, where it is filtered by the extract filter,

then air flows through the heat exchanger and is exhausted outside by the extract fan. Cold fresh air from the outside flows into the unit,

where it is cleaned by the supply filter.

Then the air flows through the heat exchanger and is directed to the room with the supply fan. Heat energy of warm extract air is

transferred to clean intake fresh air from the outside and warms it up. The air flows are fully separated while flowing through the heat

exchanger. Heat recovery minimizes heat losses, which reduces the cost of space heating in the cold season.

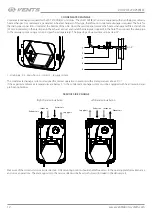

UNIT DESIGN

1

6

7

8

11

12

9

10

2

3

4

5

1 - extract fan; 2 - control unit (for VUT/VUE 270 V5(B) EC A2/A14 units); 3 - supply air filter; 4 - counter-flow heat exchanger; 5 - drain pipe;

6 - supply fan; 7 - bypass damper (only for VUT/VUE V5(B) EC); 8 - extract air filter; 9 - supply air filter (option); 10 - drain pan; 11 - external

control unit (for VUT/VUE 270 V5(B) EC A21 units); 12 - SETUP MODE button (for VUT/VUE 270 V5(B) EC A21 units).

The service side of the unit is equipped with a detachable plate for filter and heat exchanger cleaning and replacement operations. The

control unit is positioned inside the unit casing. The power cable and grounding cables are connected to the control unit via the cable

gland at the side of the unit. The temperature differential between the supply and extract air flows leads to condensate generation.

Condensate is collected in the drain pan and is removed outside through the drain pipes.

Additional components (not included in the delivery set, optionally available for purchase):

Humidity sensor

(HV2 is connected to the terminal block, HR-S is connected to the controller).

Based on the humidity sensor readings the unit keeps the set indoor humidity level. When the extract air humidity crosses the set

humidity point, the unit goes automatically to the high speed. When the indoor humidity drops down below the set point, the unit

reverts to the previous operation mode.

CO

2

sensor

(connected to the controller).

Measures indoor CO

2

concentration and sends control signal to control the fan capacity. Air capacity control based on CO

2

concentration

is an efficient energy-saving ventilation solution.

VOC sensor

(connected to the controller).

Used for quantification of indoor air saturation with cigarette smoke, exhaled air, vapours of solvents and cleaning agents for setting

sensitivity with respect to expected maximum air pollution; for local demand controlled ventilation for energy saving, as air exchange

takes place only in case of exceeding the set point of air pollution.