Service - 18

SERVICE

Cleaning and General Maintenance

For best results, and to maintain the finish of the til

-

ler, clean or wash the tiller to remove dirt and debris.

Clear all debris and dirt from the rotor and tines after

each use.

Belt Inspection

Inspecting the drive belts of the tiller

can prevent

sudden belt failure by finding problems before they

cause a belt to break.

Typical wear

on a drive

belt may

result in the

conditions

shown in the

diagram. If

any of these

conditions

occur, the drive belt will require replacement.

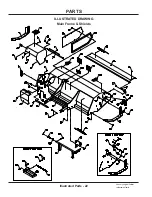

Attachment Drive Belt Replacement

1. Remove the tiller from the power unit.

2. Remove the drive pulley shield (A) from the tiller.

3.

A

Remove the old drive belt and install the new

drive belt onto the drive pulley.

4. Reinstall the drive pulley shield.

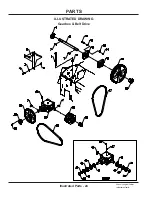

Triple Drive Belt Replacement

1. Remove the tiller from the power unit.

2. Open the belt and gearbox cover (A).

3.

A

B

C

D

Remove the drive pulley shield from the tiller.

4. Loosen the 3) gearbox plate bolts (B).

5. Loosen the locking nut (C) on the belt adjust-

ment bolt (D) and loosen the adjustment bolt.

6. Remove the old drive belts and install the new

drive belts onto the gearbox and drive shaft pul-

leys. Replace all 3) intermediate drive belts at

the same time.

7. Tighten the belt tension adjustment bolt. Refer to

triple belt tension adjustment below.

8. Tighten the 3) gearbox plate bolts. Torque to

31 ft-lbs (42 Nm).

9. Reinstall the drive pulley shield.

10. Close and fasten the belt and gearbox cover.

Triple Drive Belt Tension Adjustment

1. Remove the tiller from the power unit.

2. Open the belt and gearbox cover.

3. Remove the drive pulley shield from the tiller.

4. Loosen the 3) gearbox plate bolts.

5. Loosen the locking nut on the belt adjustment bolt

and adjust the bolt until the belts are tight.

NOTE: if the belts are overtightened, the triple

pulleys may become misaligned. If this occurs,

reduce belt tension until the pulleys are aligned.

6. Tighten the locking nut on the belt adjustment bolt.

7. Tighten the 3) gearbox plate bolts. Torque to

31 ft-lbs (42 Nm).

8. Reinstall the drive pulley shield.

9. Close and fasten the belt and gearbox cover.

Always set the parking brake, shut off power

unit engine, remove the ignition key, and ensure

all moving parts have come to a complete stop

before inspecting components or attempting any

repair or adjustment.

Attention

If any component requires replacement, use only

original Ventrac replacement parts.