32 – Part 3: Solar water heater system installation

Boiler back-up heat exchanger connection

(VELUX solar water heating system with boiler back-up only)

For installation and operation instructions, refer to the Installation/Operation manual provided with your solar storage tank.

The Installation/Operation manual for your water heater must be kept with this manual at all times.

The boiler heat exchanger connections are located in the front of the solar storage tank. Use a minimum 1” nominal tube size,

wherever you are using zone valves or circulators. The inlet of the circulator is to be connected to the hot outlet side of the

boiler. Be sure the direction of the arrow on the circulator is facing toward the flow direction from the boiler to the boiler heat

exchanger inlet of the water heater. On the water heater, the boiler return is to be connected to the return side of the boiler.

The return from heating loop should have a flow check or swing check valve installed before the return pipe from the boiler

heat exchanger.

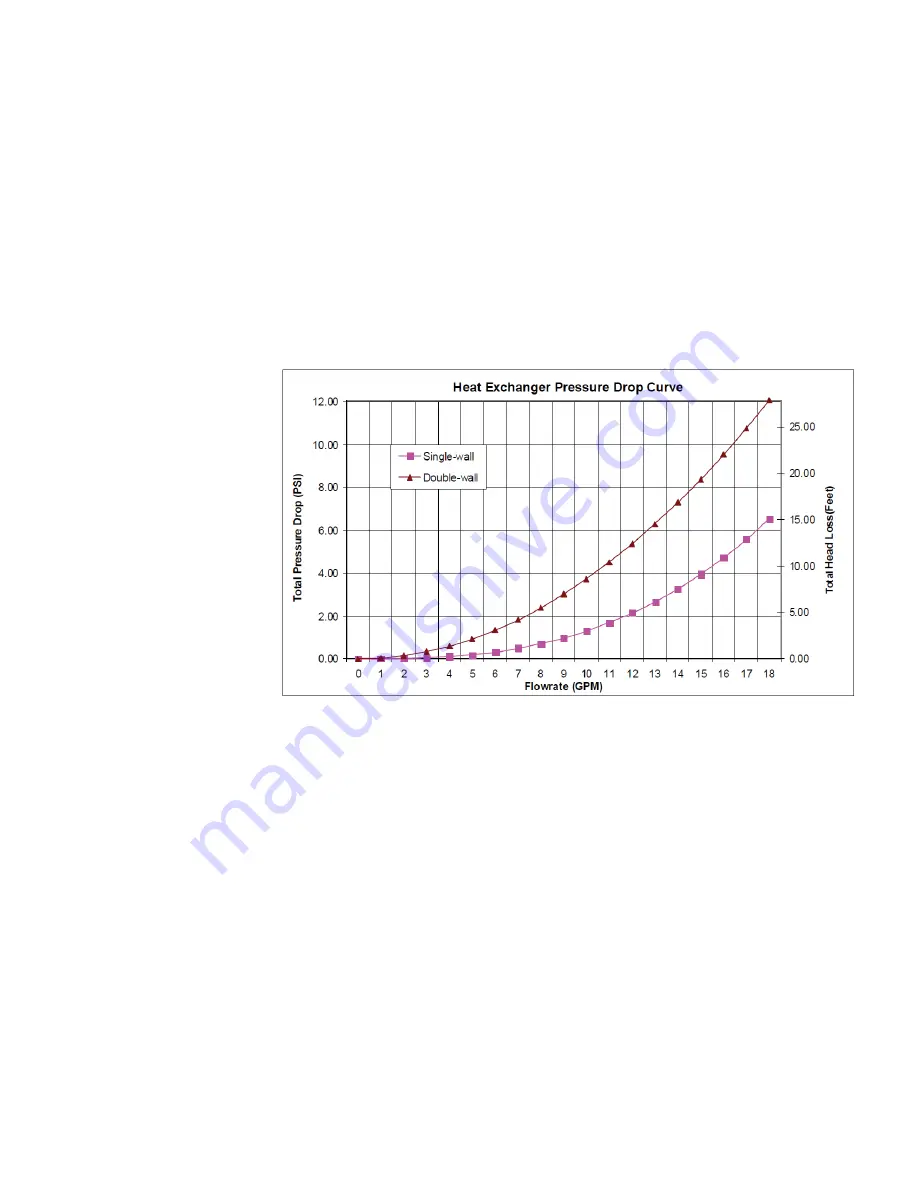

Boiler loop

circulator sizing

The boiler back-up

circulator pump must

be sized for the related

piping and pressure drop

of the heat exchanger. The

following graph represents

the pressure drop of

the solar back-up heat

exchanger. Select a 115

volt circulator pump with a

maximum current draw of

1 amp.

Charging the potable water system

Solar storage tank

Fill the solar tank with water. Do this by opening the cold water isolation ball valve to the solar tank. Inspect all fittings for

leaks. Purge all air from the potable water system by turning on several hot and cold faucets and running water for several

minutes. Air is purged when water runs continuously for 1-2 minutes without air discharge.

After the water and electrical connections have been made, the tank has been filled with water, and all air has been purged

from the tank, turn on power to heater. The heater is now operational.

Freeze protection

The propylene glycol heat transfer fluid provided acts as a freeze protection fluid and must be used to protect the system from

freezing. The VELUX propylene glycol provided is rated as nontoxic. A 40% propylene glycol/60% water mixture should be

used, however, you must use a mixture most appropriate for your climate. Do not use a higher glycol to water concentration

than necessary, as this will adversely impact heat transfer efficiency. See the propylene glycol Data Sheet in the back of this

manual for recommended concentrations. A copy of the MSDS sheet must be left with the end user of the solar system. See

“Propylene glycol emergency overview” as part of the propylene glycol Data Sheet in the back of this manual. The collector

loop must be charged with a mixture of heat transfer fluid and distilled or deionized water. The use of regular tap water as a

mixing agent is prohibited. Scheduled maintenance must be established to monitor and maintain the proper PH level of the

heat transfer fluid in the system to protect the heat exchanger and other components in the system.