10

3 Product description

VEGACAL 66 • Foundation Fieldbus

30038-EN-200929

3.2 Principle of operation

VEGACAL 66 is a level sensor for use in non-abrasive liquids and bulk

solids.

The cable probe is fully insulated. The proven mechanical construc-

tion offers high functional safety.

Probe, measured product and vessel wall form an electrical capacitor.

The capacitance is influenced by three main factors.

1

2

3

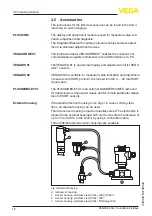

Fig. 3: Functional principle - Plate capacitor

1 Distance between the electrode surfaces

2 Size of the electrode surfaces

3 Type of dielectric between the electrodes

The probe and the vessel wall are the capacitor plates. The measured

product and the insulation are the dielectric. Due to the higher dielec-

tric constant of the insulation and the conductive product compared to

air, the capacitance increases as the probe is gradually covered.

The capacitance as well as the resistance change are converted by

the electronics module into a level-proportional signal.

Power is supplied via the H1 Fieldbus. A two-wire cable according to

Fieldbus specification serves as carrier of both power and digital data

for multiple sensors. This cable can be operated in two versions:

•

via an H1 interface card in the control system and additional power

supply

•

via a Linking device with HSE (High speed Ethernet) and addi-

tional power supply according to IEC 61158-2

The DD (Device Descriptions) and CFF (capability files) necessary

for planning and configuration of your FF (Foundation Fieldbus) com

-

munication network are available in the download area of the VEGA

homepage www.vega.com

. The appropriate certificates are also

available there. A CD with the appropriate files and certificates can be

ordered via e-mail under [email protected] or by phone from one of

the VEGA agencies under the order number "DRIVER.S".

The backlight of the display and adjustment module is powered by the

sensor. Prerequisite is a certain level of operating voltage.

The data for power supply are specified in chapter "

Technical data

".

Application area

Functional principle

Power supply and bus

communication

DD/CFF