3

Wanner Engineering, Inc.

United States

Instant Information: www.vectorpump.com

(61) 33-5681 Fax (61) 33-6937 VEC-991-400A

Vector Series Installation

Pump Test and Installation

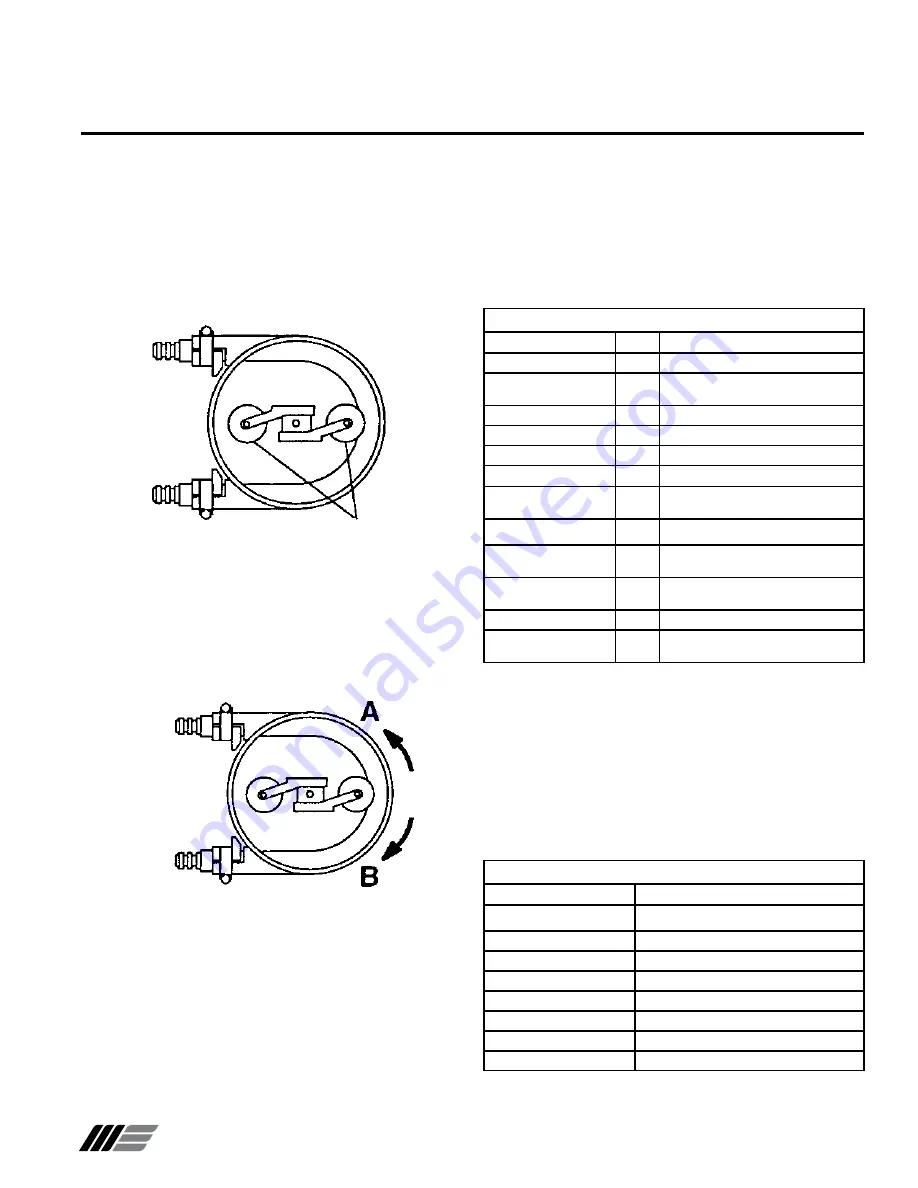

Before you install the pump in the system, set the direction of

pump rotation and the position of the pressure rollers:

1. Remove front cover from pump (four screws).

2. See Figure 1. For easier adjustment, check that pressure

rollers are in position shown (one roller compressing middle

of hose, and one roller free).

Note:

Model 2006 and 2007 pumps use a different rotor

assembly than the one shown.

Before Initial Start-Up

Before you pump fluid through the system, be sure that:

1. All shutoff valves are open.

2. All connections are tightly secured.

3. See Hose Identification Table. Hose material is compatible

with fluid being pumped, and hose design matches duty cycle

and discharge pressures.

Material Operating Temperatures

Material

Operating Temperatures

EPDM

0 to 180˚ F

Hypalon

0 to 180˚ F

Neoprene

50 to 130˚ F

Silicone

0 to 180˚ F

Varprene

0 to 160˚ F

Natural Rubber

0 to 185˚ F

Nitrile Rubber

0 to 160˚ F

Pharmed

®

0 to 180˚ F

Hose Identification

Extruded

Code

Description

Hypalon

HE

Black color, shinny smooth surface

Neoprene

PE

Flat black color, rough surface, rubber

smell

Varprene

VE

Cream color, smooth surface

Silicone

SE

Rust color, smooth surface

Pharmed

®

FE

Cream color, Pharmed

®

name on hose

Fiber Braided

Hypalon

HF

Black color, yellow stripe, double

braided

EPDM

EF

Black color, white stripe, double braided

Natural Rubber

NF

Black color, green stripe, double

braided (standard duty)

Natural Rubber

MF

Black color, no stripes, thick double

braids (heavy duty)

Nitrile Rubber

BF

Black color, white inner hose

Nitrile Rubber - Oil Rated

OF

Black color, HBRF-HY-K stamped on

hose

W0455

W0456

Pressure

Rollers

Figure 1

W0456

DISCHARGE

INLET

Figure 2

3. Connect incoming power supply to motor (refer to motor

manufacturer’s instructions).

4. See Figure 2. Run pump and check direction of rotation,

“A” or “B” as shown. All pumps must rotate in direction “A“

(counterclockwise). To reverse rotation, exchange two of

three wires that connect incoming power to motor.

5. Set pressure rollers (see “Service: Setting the Roller

Pressure”). Roller pressure is not set at factory, because it

must be adjusted to compensate for size of inlet and discharge

lines and specific gravity of fluid being pumped.

6. Verify all fasteners are properly tightened.

7. Reattach front cover.

8. Install pump in system.

4. See Material Operating Temperatures Table. Temperature of

fluid pumped is within operating temperature range of hose

material installed in pump. Hose material can be identified by

5

th

and 6

th

digit of pump model number. E.g. 2007-NF-BB-D2,

where ‘NF’ designates natural rubber.

CAUTION

: Contact factory when pumping a fluid that is

within 15˚ F of the maximum hose temperature. Take safety

precautions to insure hot pumpage does not harm operators

if a hose leaks.