S

2.9.7

F

c

2

C

Safety infor

The rele

is opera

pump”,

Assumin

ensure t

occur in

pumped

(e.g., du

7 Maintena

For safe and

condition. Th

The actu

conditio

caused

Regular

auxiliary

proper f

2.9.8 Safe

Wear ap

Avoid l

get cau

meets

hearing

Do not

not com

couplin

parts. D

CAUTION!

S

t

rmation:

evant admis

ated at a hig

contact the

ng an ambie

that temper

n the event o

d medium. O

ue to evapo

ance

d reliable o

his also app

ual service

ons on site.

by overhea

rly monitor v

y systems a

functioning.

ety and acc

ppropriate c

loose garme

ught in mov

safety regu

g protectors

t perform an

me close wi

ngs, etc.) D

Do not step

Switch the

the plant.

ssible opera

gher temper

manufactu

ent tempera

rature class

of an insuffi

Operating th

oration in the

operation, m

plies to the f

life of the a

Regular che

ated bearing

vibration be

are installed

cident preve

clothing whe

ents with loo

ving compon

ulations: glov

s and helme

ny maintena

ith your han

o not come

p on the mot

motor off

ating tempe

rature and n

rer for the m

ature of 40°

s T4 is main

iciently filled

he pump ou

e interior).

make sure t

function of t

antifriction b

ecks of the

gs, start-up

ehaviour to e

d, check to s

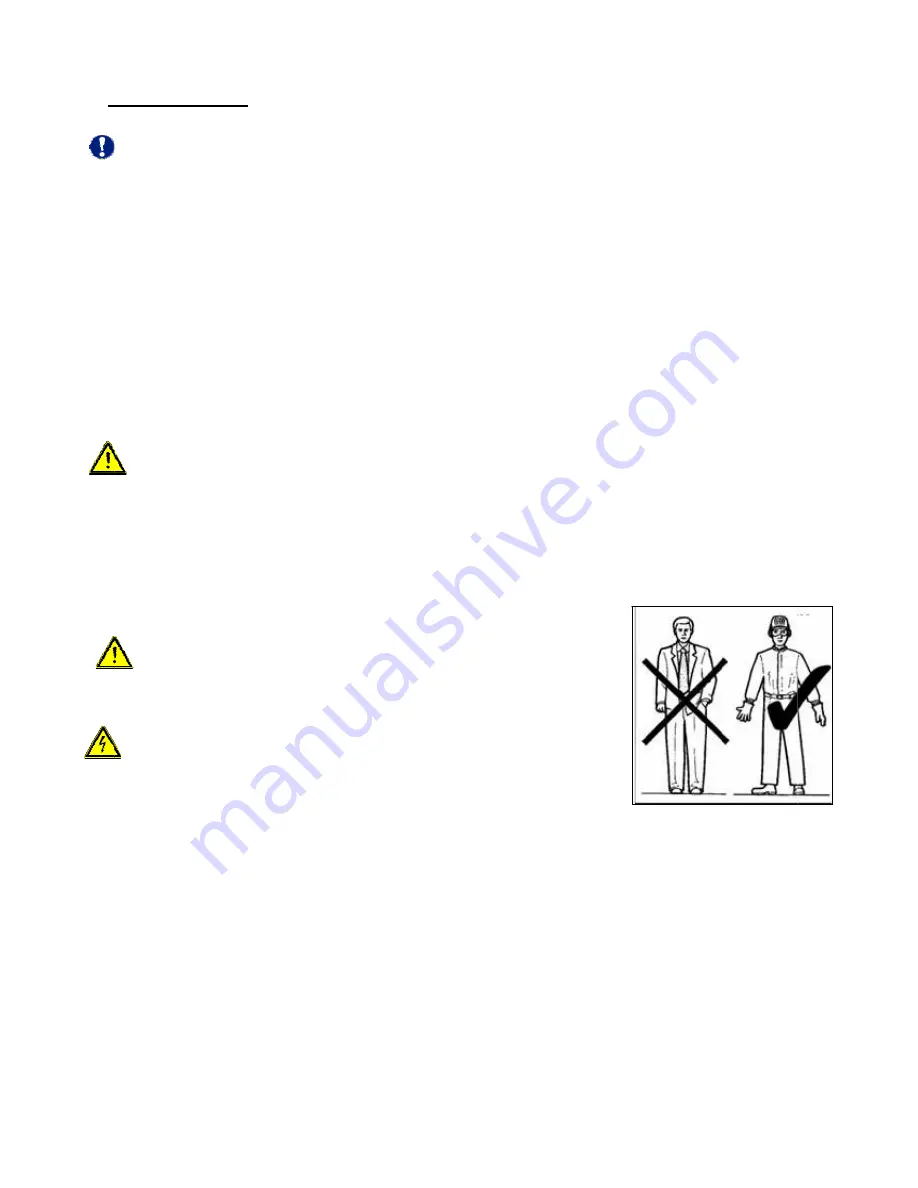

ention stan

en working

ose parts (t

nents. Wear

ves, insulat

et (see figur

ance work w

nds to any m

e close with

tor pump to

in case of

Page

11

rature of the

no data she

maximum a

°C, grease l

tained for th

d interior, b

utside the ad

the unit is p

the antifrictio

bearings dep

running no

of the exter

ensure the

see whethe

ndards

in the vicini

ies, scarves

r protective

ting footwea

re on the rig

with the mot

moving parts

your hands

o perform in

emergency

e pump is in

eet is availa

dmissible o

ubrication a

he antifrictio

ut also in th

dmissible ra

properly ser

on bearings

pends on th

ise prevent

rnal rotor on

proper func

r monitoring

ty of the pu

s, etc.) that

clothing tha

ar, goggles,

ght).

or running.

s (e.g. belts

s to hot mot

terventions

y. Inform th

ndicated in

ble or the p

operating te

and proper

on bearings

he presence

ange may a

rviced and

s.

he mode of

the risk of

n the lanter

ctioning of th

g facilities s

mp.

could

at

Do

s,

tor

.

he personn

the data sh

pump is use

mperature o

maintenanc

s. Dry-runni

e of high ga

also lead to

kept in per

operation a

excessive t

n or defecti

he plain bea

should be in

nel respons

heet. If the p

d as a “poo

of the pump

ce and oper

ng may not

s contents

dry-running

rfect technic

and the spec

temperature

ve bearing

arings. If

nstalled to e

sible for

pump

ol

p.

ration,

t only

in the

g

cal

cific

es

seals.

ensure

Summary of Contents for V 100-2

Page 1: ...Operating Manual V Series Internal Gear Pumps with Magnetic Coupling ...

Page 34: ...Page 34 ...

Page 35: ...Page 35 ...