---15---

C. General description

3

2

1

4

T C36

4a

5

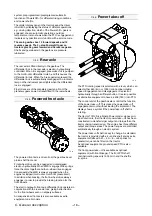

Front view of tractor:

1 DIN---socket for current, max 8A (current on, when the

parking lights are on)

2 Auxiliary hydraulics quick couplings (with front linkage,

extra equipment)

3 Front power take---off (extra equipment)

4 Front linkage (extra equipment)

4a.External push buttons for front lift (together with front

lift), for more details see page 233.

5 Implement control system Isobus (extra equipment), for

more details see page 202.

C 2.

Service

In order to function satisfactorily the tractor must be

properly maintained. The necessary daily lubrication and

routine checks can, of course, be carried out by the

operator.

Where adjustments and repairs are necessary which

require the attention of a qualified mechanic and the use

of special tools, it is advisable to rely on a workshop. In

this case we advise you to consult your local dealer as to

how your tractor should be looked after as he is in a

position to give you the best possible service. Through

service bulletins and special training courses he is kept

constantly informed of the factory’s recommendations

regarding care of the tractor.

C 2.1.

Cost---free service

Before leaving the factory the tractor was thoroughly

tested and adjusted to ensure it is in first-class condition

when delivered to you. However, it is important that the

tractor is given further checks during the first period of

operation.

Bolts must be checked for tightness, various settings

inspected and other minor adjustments made. Your dealer

therefore provides a cost---free service inspection

(excluding oil and filter costs) after 100 hours running.

C 3.

Engine

T1LS C6

All the tractors have 4---stroke, 4---valves, six---cylinder,

turbocharged and intercoolered multi power common rail

direct injection diesel engines.

Two power ranges

--- The models T151eLS, T161LS and T171LS have also a

larger transport boost power area, when the main gear

is H2 or higher.

--- On the model T151eLS it is possible to choose either

low engine range (maximum 1800 r/min) or standard

engine range (maximum 2200 r/min) with the “ECO”

switch. On the low engine range the fuel consumption,

and the emissions are lower and the noise will be redu-

ced. On the low engine range there are also Transport

boost range in use.