4SK70EN - 5/2023

12

4 Installation

WARNING!

Crushing and cutting hazard.

Do not put your hands or fingers into the tower or

port areas when the valve cycles.

Do not energize the actuator before the valve is

properly attached to the pipeline.

Disconnect and de-energize the actuator before

installation and maintenance work.

High pressure injection hazard.

Do not use higher pressure than rated for the valve.

Higher pressures can cause serious damage to the

valve or harm to operating personnel.

CAUTION!

Harmful substance hazard.

If the process medium has to be fully contained, is

corrosive or harmful, make sure the flushing ports

are piped to a safe location.

Never use the valve with all flushing ports

plugged. Accumulated solids can cause the valve

to jam.

4.1 General

Flowrox gate valves are normally delivered fully assembled

and ready for use. Only personnel with appropriate training

are allowed to install the valves. If the valve is delivered

without an actuator or accessories, they must be installed in

accordance with the manufacturer’s instructions.

Flowrox gate valves have connections with DIN or ANSI

bolt drillings as standard design, but other drillings are also

available, such as BS, AS, JIS.

Reserve enough space for safe installation and maintenance.

See

Appendix A

for valve dimensions. Notice that during

opening and closing cycles, a small amount of medium is

discharged in the valve body cavity; therefore do not install

gate valves above walkways or critical components. Flushing

and drainage connection must be installed if medium is

harmful or corrosive.

If the valve has been stored in the warehouse, lubricate the

valve as instructed in the

Lubrication

chapter.

4.2 Flow direction, support, and valve

position

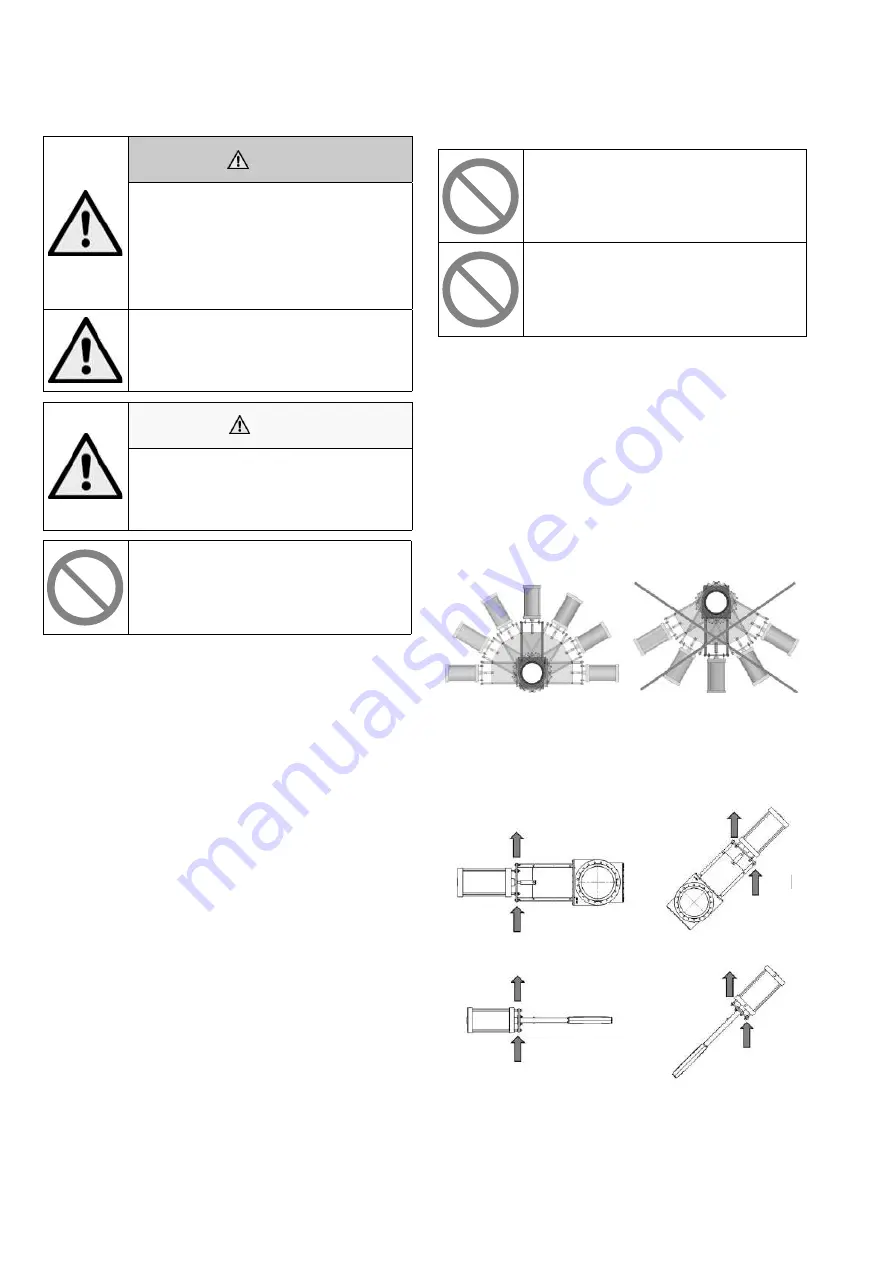

Do not install DN250 or larger valves in other

than vertical position without support.

Do not step on a valve installed in horizontal or

angled position.

The valve does not have an intended flow direction; therefore

it can be installed either way in the pipeline.

Proper pipe support must be placed on either side of the valve

to support the weight of the pipe. The valve must never be

used to support the pipes.

The valve can be installed in any position other than below

horizontal. Flushing will not work in installations below

horizontal level and it will lead to leaking and nonfunctional

valve. See the following Figure 7.

Recommended installation

positions

Forbidden installation positions

Figure 7. Installation alternatives for SKW and SKF

valves.

Horizontal installation.

Support is required as shown or

otherwise.

Angled installation.

Support is required as shown or

otherwise.

Figure 8. Support for automatically actuated valves.

Summary of Contents for Flowrox SKW DN50-600

Page 1: ...Valmet 4SK70ZHS 6 2022...

Page 2: ...4SK70ZHS 6 2022 2...

Page 3: ...3 4SK70ZHS 6 2022...

Page 4: ...4SK70ZHS 6 2022 4...

Page 5: ...5 4SK70ZHS 6 2022...

Page 6: ...4SK70ZHS 6 2022 6 2 0 to 75 7 2 3 4...

Page 7: ...7 4SK70ZHS 6 2022 H...

Page 8: ...4SK70ZHS 6 2022 8 2 3 4 2 2 5 6 7 8 4 2 2...

Page 9: ...4SK70ZHS 6 2022 2 3 4 2 2 5 6 7 8 4 2 2...

Page 10: ...4SK70ZHS 6 2022...

Page 11: ...4SK70ZHS 6 2022 3...

Page 12: ...4SK70ZHS 6 2022 4...

Page 13: ...4SK70ZHS 6 2022...

Page 14: ...4SK70ZHS 6 2022...

Page 15: ...4SK70ZHS 6 2022 5 6...

Page 16: ...4SK70ZHS 6 2022 4 2 7 cm3 cm3...

Page 17: ...4SK70ZHS 6 2022...

Page 18: ...4SK70ZHS 6 2022...

Page 19: ...4SK70ZHS 6 2022 Nm...

Page 20: ...4SK70ZHS 6 2022 20...

Page 21: ...4SK70ZHS 6 2022...

Page 22: ...4SK70ZHS 6 2022 22 DN D F U K N S V W H H H D F U K N S V W H H H...

Page 23: ...23 4SK70ZHS 6 2022 DN D F U K N S V W H H H D F U K N S V W H H H...

Page 25: ...25 4SK70ZHS 6 2022 2 3 4 5 6 7 8 0 2 4 S2 S3 S4 S5 S6 S7 S8...

Page 26: ...4SK70ZHS 6 2022 26 F F5 H S S5 Z2 Z3 Z5 Z6...

Page 27: ...27 4SK70ZHS 6 2022 Z7...

Page 28: ...Valmet 4SK70ZHS 6 2022...